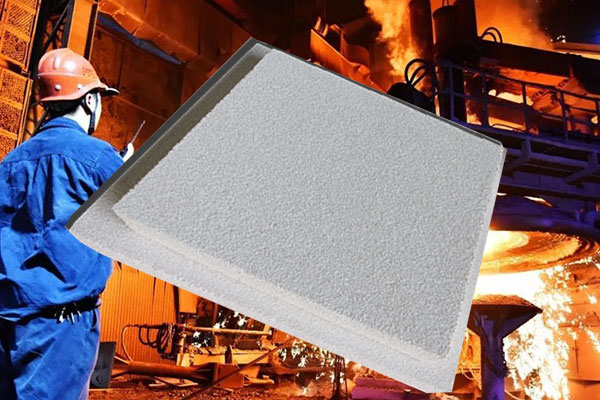

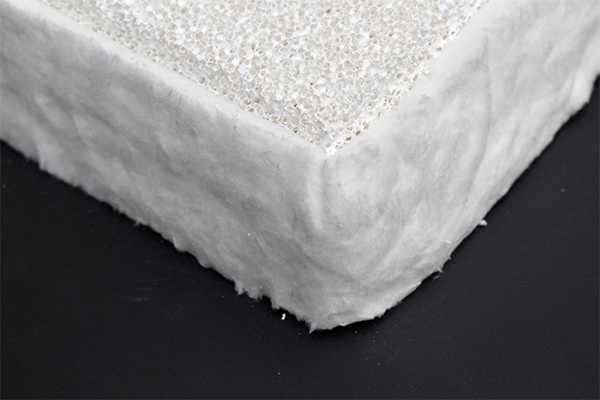

Ceramic Filters UAE Aluminum is mainly used in foundries and foundries to filter aluminum and aluminum alloys. It can effectively remove inclusions, reduce trapped gas, and provide laminar flow when aluminum liquid is filtered. Foam ceramics have the characteristics of light weight, high mechanical strength, large specific surface area, high porosity, good thermal shock resistance, […]

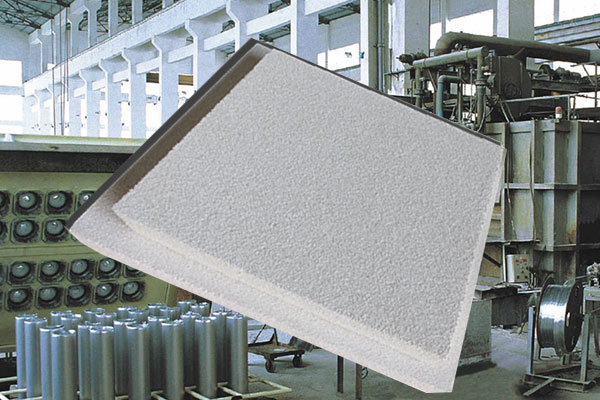

Ceramic Filters New Zealand Aluminum is a new type of filter with low density, high porosity and a three-dimensional network framework structure. It is widely used in the aluminum processing industry to filter molten aluminum to improve the quality of aluminum. Ceramic Filters for New Zealand Aluminum Casting is the first cost-effective medium to remove […]

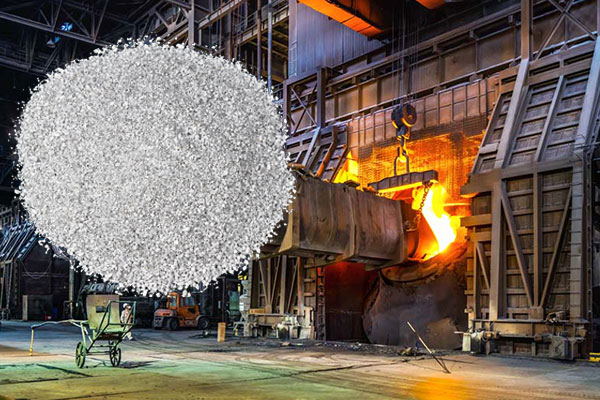

Flux for Dutch Aluminium is a white (slightly gray) powdery fine particle with a major component of chloride and fluoride and other compounds. After proper heat treatment and sieving, the particle size is uniform, which is beneficial to the uniformization of the refining tank under the action of carrier gas (N 2 or Ar) into […]

Granular Flux Montenegro Aluminum solves the problem of refining effect in the traditional use of a large amount of aluminum ash, Aluminum Casting Flux tons of aluminum 1.5-2.0kg, discharge aluminum ash 0.8-1%, and achieve high-precision aluminum alloy casting Requirements, effectively improve the yield of metal liquid 0.6-0.8%, to achieve energy saving and consumption reduction purposes. […]

Refining Flux Romanian Aluminium uniformly enters the lower layer of aluminum by the powder-carrying refining tank under the action of carrier gas (N or Ar). Through the physical and chemical changes, numerous small bubbles are formed in the aluminum liquid to fully contact the aluminum liquid, and the aluminum liquid is separated [H] and other […]

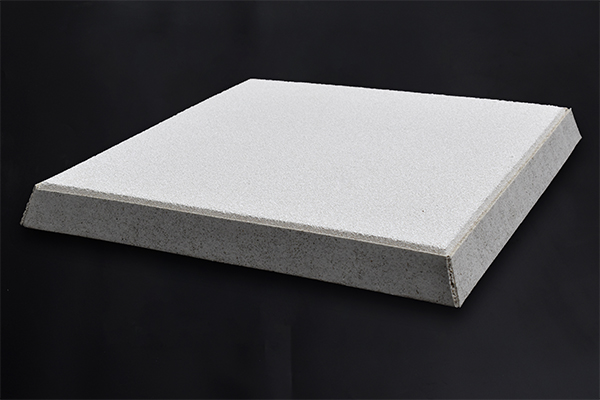

Ceramic Foam Filter Canada Aluminium provides a cost-effective method to remove inclusions in aluminum melt for foundry. The removal efficiency may vary depending on the application conditions. Generally, efficiency increases as the size of the filter unit and the speed of metal in the filter decrease. Ceramic Foam Filter Function -Reduce waste related to inclusions. […]

Ceramic Filter Cameroon Aluminium filtration efficiency is closely related to its correct installation and use. It is also necessary to prevent re-contamination of the filtered clean aluminum liquid. The size of the ceramic foam filter plate must be selected according to the flow range of the specific casting type, the maximum level of the metal […]

Ceramic Foam Filter Brazil Aluminium can effectively remove various impurities in the aluminum melt, greatly improving the cleanliness of the metal, thereby improving product quality, reducing costs, and improving productivity to varying degrees. Ceramic Foam Filter operation is simple, the process is easy to control, does not require excessive investment, and is worthy of promotion […]

Launder with baffle system facilitates the removal of floating particles from the fluid and deposits these particles in the launder. The flow trough is provided with a launder baffle system, which is located on its side, and is used to promote the static of the fluid circulating in the flow trough, thereby promoting the precipitation […]

Casting Launder for Molten Aluminium cross section is a U-shaped opening and widening upwards, the molten metal flows in the launder structure. The inner surface of the launder in contact with the molten metal is defined by a refractory material, such as a ceramic wear-resistant composition. The refractory material forms a flow channel for the […]