Ceramic foam filter is increasingly used in the aluminum industry. These are special filters made from materials such as silicon carbide and aluminum oxide, which give them structural stability and resistance to thermal shock.

The ceramic foam filter removes oxides from the aluminum surface and thereby improves the quality of the casting. Today more and more aluminum sheet and foil manufacturers use these filters.

Adtech is one of the largest ceramic foam filter factories in India as well as the global industrial market. The company supplies these high quality aluminum sheet and foil filters to its customers.

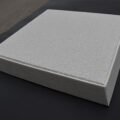

Adtech, a supplier of foam filters, is used to filter molten aluminum in foundries. Our filters have a three-dimensional mesh structure, high porosity and low bulk density. Due to properties such as high temperature resistance and corrosion resistance, these filters are popular with customers.

These products prevent unwanted metal penetration from molten metal, which reduces casting rejects and increases productivity. These filters will not clog even with a large amount of impurities in the molten aluminum.

Ceramic foam filter is mainly used for the filtration of aluminum and aluminum alloy in the foundry industry. With excellent thermal shock and erosion resistance, they can effectively remove inclusions, reduce entrained gas, and provide a laminar flow to keep the molten metal clean.

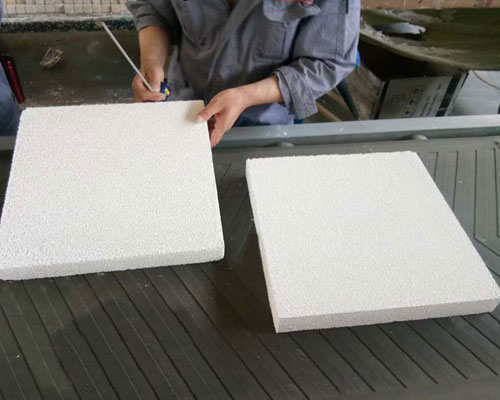

The ceramic foam filters, specially designed by AdTech, are made from the main raw material – aluminum oxide. They are manufactured with porosities ranging from 10 to 60 pores per inch (PPI). In addition, combo kits are available in 20-30 PPI resolution and other choices are possible. Filters of different sizes and individual ones are produced according to the specifications.

The filtration efficiency of a die-cast aluminum ceramic foam filter is largely dependent on its correct installation and use. At the same time, the usual and necessary measures taken to reduce the occurrence of inclusions in technological operations such as smelting, furnace treatment and casting cannot be ignored, since the filtration process is applied. It is also necessary to prevent re-contamination of the purified aluminum liquid after filtration.