The foam ceramic filter experiment is detailed and complex. This article will list them one by one.

Bach filtration experiments were conducted using -5000 g of molten charge, i.e. 90 wt % of the aluminum alloy A356 doped with 10 wt % A356composites, containing 15 wt % Sic particles with a particle size ranging from 13 to 23 um. The melt was heated to 750 C in a high-frequency induction furnace, i.e. one separate melt for each batch filtration experiment. The experimental filtration set-up was energized at 50 Hz, and the molten metal was poured into the apparatus until a metallic head of -100 above the filter was reached. Experiments were conducted for each filter grade at 3 and 10 minutes. Gravity reference experiments were also performed for each filter grade. Unique trials to investigate the required gravity priming height of different grade foam ceramic filter experiment studies were also executed. For the metallographic evaluation of the obtained results12 samples were extracted from each filter element. Scanning Electron Microscopy ( SEM ) was used to analyze the samples using the Back ScatteredElectron ( BSE ) mode. The magnetic field density was estimated using FEM by integrating from the bottom to the top of the innermost coil along the surface of the workpiece, and the average Lorentz force along the surface of the filter integrated from the bottom to the top of the filter. The Lorentz force obtained under the filter was, however, integrated from the bottom of the liquid metal to the bottom of the filter.

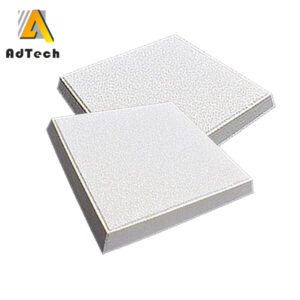

foam ceramic filter

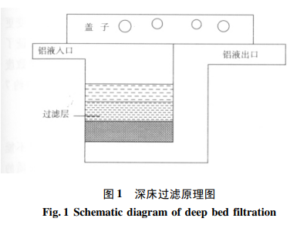

In Fig . 1 the experimental apparatus used ( i ) for the 50 and 80 PPI experiments, ( i1 ) for the FEMcalculated flow field for a 50 PPI foam ceramic filter experiment, and ( iii ) for the calculated induced Lorentz forces on the outer surface of the workpiece is presented. It should be mentioned that due to the effect of the Lorentz forces the flow velocity inside the filter is estimated to be one order of magnitude higher compared to normal industrial casting conditions ( as indicated in Fig . 1 ) . Typical experimental data and FEM model results are summarised in Table 1COMSOL FEM simulation of the now field ( arrows and shading ), as well as the Lorentz forces ( cones ), for a 50 PPI foam ceramic filter experiment The applied conditions are summarised in Table 1. A detailed description of the coil design has been presented in earlier papers by members of the present research group / -13

foam ceramic filter experiment