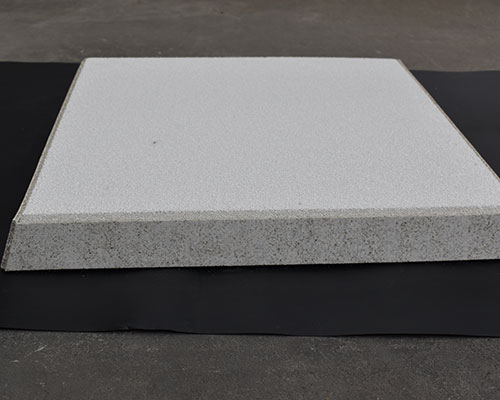

Foam Ceramic Filter Alcan Smelter is one of the key points in the smelting process of alloying, cleaning and refining aluminum waste.

Casting ceramic filter can remove non-metallic inclusions in aluminum alloy melt. It is treated with flux in an oven. The foam ceramic filtration technology has become an important method to purify liquid aluminum.

Foam Ceramic Filter Alcan Smelter is specially developed for aluminum casting workshop to produce high-quality casting products. Can reduce the waste caused by impurities, reduce the cost caused by impurities, achieve faster extrusion or hot rolling speed, improve productivity, easy to replace the alloy. No need to detain metal to increase casting flexibility.

Foam Ceramic Filter can effectively remove various impurities in liquid Aluminium, thus greatly improving the purity of the metal, thereby improving product quality, reducing costs and improving productivity to varying degrees.

The operation is simple, the process is easy to control, does not need too much investment, worthy of promotion and application.

Foam Ceramic Filter liquid Aluminium purification processes and equipment are suitable for all Aluminium production sectors including book reels, strips, foils, rods, tubes, lines, extruded parts, forgings, raw Aluminium ingots, recycled ingots and continuous casting.

Ceramic Filter Solution

Adopt better ceramic filter to filter aluminum melt (foam ceramic two-stage filtration, high adsorption capacity). Change the replacement method of ceramic foam filter.

Choose good primary aluminum and scrap.

From casting to solidification, the casting alloy liquid will have macroscopic or microscopic shrinkage at the solidified place.

This macroscopic contraction caused by contraction is visible to the naked eye and can be divided into concentrated contraction and dispersed contraction.

Concentrated shrinkage pore size is large and concentrated, distributed at the top of the casting or thick section of the hot joint.

The dispersed shrinkage cavity disperses fine, and most of it is distributed in the casting shaft and hot joint.

Microscopic shrinkage pores are hard to be seen by naked eyes and most of them are distributed under grain boundaries or between dendrites.

Alcan Smelter’s BC Works operations in Kitimat, British Columbia include a newly modernized aluminum Smelter and Kemano Powerhouse, a hydroelectric power facility supplied by the Nechako Reservoir. From the West coast of Canada, we transport our products by ship and rail, mainly to customers in Japan, Korea and the United States.