The foam filter manufacturers’ selection, that’s a problem, this article tells you what to choose based on

1 Correct selection of filter plates to improve the cleanliness of aluminum melt

(1) The selection of the foam ceramic filter plate and foam filter manufacturers‘ selection should first be determined according to the impurity content in the aluminum melt, the melt transfer flow rate, and the quality requirements of the cast aluminum products

- The aluminum melt contains a lot of impurities, and the quality requirements of the casting products are general. You can choose a foam ceramic filter and foam filter manufacturers‘ with a larger hole mesh and add a glass cloth in front of the filter plate for coarse filtration. In this case, it is important to use glass wool cloth for coarse filtration when casting aluminum melt semi-continuously, which can intercept the slag flowing out when the furnace is opened and the slag washed off from the launder to prevent the filter plate from being blocked.

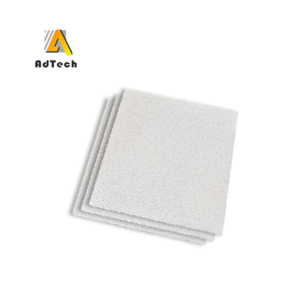

②When the quality requirements of casting products are high, a new generation of foam ceramic filter plates and foam filter manufacturers‘ selection with large mesh numbers are used. For example, Fujian Ruimin Aluminum Co., Ltd. and Nanfang Aluminum Co., Ltd. produce aluminum foil blanks, and Henan Mingtai Aluminum Co., Ltd. produces high-quality Hot-rolled slab Northeast Light Alloy Co., Ltd. produces high-quality military aluminum, and Guangdong Zhongshan Hesheng Aluminum Co., Ltd. uses the second-generation foam ceramic filter produced by Fuzhou Maitexin High-Temperature Material Co., Ltd. If the 30pil and 60p ceramic plates with the specifications of 305mm × 305mm × 50mm, 38lmm × 381mm × 50mm, 432mm × 432mm, 08mm × 508mm × 50mm are used for double-stage filtration, the aluminum melt can better achieve the ideal cleanliness.

foam filter manufacturers

③ The selection of filter plate specifications is determined according to the flow rate of aluminum melt per unit time and the total throughput of aluminum melt. If the flow rate is large and the total throughput is large, and the aperture of the filter plate is small, the larger size filter plate is selected.

(2) When choosing a filter plate, you should also observe its color, shoot its body, and burn its objects.

- The color of the filter plate is pure and free of impurities, indicating that the material is uniform; it is sticky but not sticky, indicating that the surface is not sprayed with adhesive, which will not cause secondary pollution of aluminum liquid.

- Hold the filter plate with one hand, slap the filter plate with the other palm, and continuously drop the ceramsite, which means that the inferior filter plate will cause secondary pollution of molten aluminum.

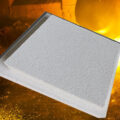

③ Use an open flame or electric heating to heat the filter plate to red and immediately cool it at room temperature without cracking and slag, it is a good filter plate

(3) When purchasing a filter plate, the effective specific surface area or pores of the foam should be carefully evaluated to observe the uniformity of the mesh on the surface of the filter plate, and then cut open to observe the mesh uniformity of the section. If possible, the porosity can be calculated by the drainage method. If the three-dimensional mesh is uniform and the porosity is relatively large, it is an excellent foam ceramic filter plate.