Factors affecting foundry aluminum casting loss include liquid aluminum temperature, contact strength between liquid aluminum and oxygen, and aluminum content in aluminum slag.

Ways to Reduce Foundry Aluminum Casting Damage

1. Control the temperature of liquid aluminum

The melting point of aluminum is 660 ℃. Generally speaking, the casting temperature of primary aluminum is controlled at about 730 ℃, or even lower. The aluminum alloy has better fluidity and the casting temperature is lower than that of primary aluminum, about 710℃-730℃. When the temperature of aluminum liquid is high in the mixing furnace, add aluminum alloy to the furnace in time. So that the temperature decreases. The surface of the cold material should be clean and free of oil stains, otherwise it will burn and release heat to promote burning. In short, the temperature of the molten aluminum is effectively reduced to the corresponding casting temperature, which can reduce the huge impact of the temperature on the casting loss.

2. Reduce the contact strength between the foundry aluminum liquid and the air

The greater the contact strength between the liquid aluminum and the oxygen, the more severe the oxidation burning, and the greater the casting loss. AdTech insulation covering agent is used in the aluminum alloy smelting process to prevent oxidation and oxygen absorption on the melt surface.

(1) Reduce the contact time between liquid aluminum and oxygen

Under the condition of meeting the production requirements, the liquid aluminum in the furnace is turned into the finished product as soon as possible, and the liquid aluminum should not stay in the furnace for too long.

Reasonably arrange the casting equipment, shorten the length of the flow cell as much as possible, so as to reduce the exposure time of liquid aluminum in the air. At the same time, the aluminum silicate insulation board can be covered on the upper part of the flow cell, which not only has a certain insulation effect, but also reduces the oxygen content in the flow cell.

(2) Control the liquid aluminum stirring method

Whether it is manual stirring or mechanical stirring, it will not only bring huge fluctuations in the liquid level, increase the contact area with oxygen, but also increase the oxygen content in the furnace. It is bound to accelerate the chemical reaction. So it needs to control the liquid aluminum stirring method, and reduce the fluctuation of aluminum liquid.

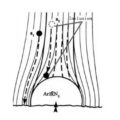

(3) Control the bubble-blowing height during aluminum refining

The general refining method is to manually sprinkle the refining agent into the furnace, and then perform stirring refining. But for some alloy production, nitrogen blowing refining is required (the refining time is longer, up to about 30 minutes). And there must be a certain blowing height. It is best to adjust the nitrogen pressure, and control the height of the bubble to 10-15mm.