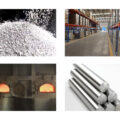

The granular refining flux has a good effect of removing slag and impurities in the aluminum melt.

The principle of slag removal is: when the Non-Sodium Granulated Flux is sprayed into the aluminum melt by inert gas, the solid particles can quickly melt into droplets. Because the density of these droplets is less than that of the aluminum melt, the surface tension of the slag inclusions is smaller. Has a strong ability to wet and adsorb slag inclusions. When the slag inclusions are absorbed by the flux droplets, they float up and are removed from the melt. At the same time, after the flux droplets float up, a liquid layer is formed to cover the surface of the aluminum melt, thereby reducing the oxidative burning loss of the aluminum melt.

The principle of impurity removal is: after the magnesium ion-containing compound in the refining agent enters the aluminum melt, it will react with the alkali metal elements to release the magnesium atoms into the aluminum alloy melt, and at the same time bring the alkali metal elements absorbed by the reaction to the surface of the aluminum melt, thereby removing the alkali metal.

Compared with the traditional powder mixed refining agent, the advantages of refining aluminum alloy melt with granular refining flux are very obvious:

- The granular refining agent removes the alkali metal in the aluminum alloy melt, especially the effect of Na, Li, Ca is very significant.

- The granular refining agent is a non-exothermic flux, which can significantly reduce the oxidation burning loss of aluminum; compared with the traditional powdered refining agent, it can reduce the oxidation burning loss of aluminum by more than 1 kg per ton of aluminum alloy melt.

- After refining with granular refining agent, the cleanliness of aluminum alloy melt is significantly higher than that of using traditional powder mixed refining agent.

- During the refining process, the granular refining agent reacts fully with the aluminum alloy melt, and its amount can be greatly reduced. It is a highly efficient refining agent. Usually, only 0.5 kg to 1 kg of refining agent is used per ton of aluminum alloy, which is better than traditional powder mixing. The amount of type refining agent is less than half.

- The granular flux is a smokeless and dust-free environmentally-friendly refining agent, which can ensure that the level of particulate matter emitted by the chimney does not exceed the standard.