Before molten metal is poured into the casting nozzle, it is preferred to heat the nozzle to minimize warpage and to avoid prematurely cooling the molten metal. However, with refractory materials, it is difficult to heat the nozzle uniformly.

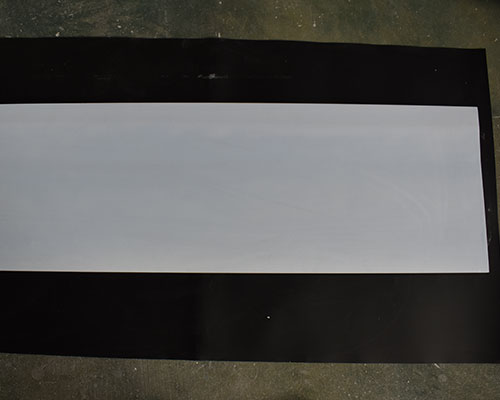

To minimize sagging experienced with nozzles, use of spacers. A nozzle having a lower plate and an upper plate separated by cross pieces. Outside of the nozzle is an extension on either side of the nozzle referred to as a cheek which is divergent. use of baffles to control the flow of molten metal to a casting machine.

Casting tips determine the width of the aluminum sheet during continuous casting. Casting tip sections create a cavity in conjunction with spacers, allow the flow of metal through the casting tips just before the solidification of the sheet. AdTech ceramic fiber castertip is used for crystallization forming and size control of aluminum plate in the casting production line. It adopts nano-scale fiber composite material, and the process by high-precision equipment. AdTech casting tips and the nozzle has moderate density, good thermal insulation, precise size, high oxidation resistance, and low deformation.

The molten metal cast-rolling casting nozzle includes a narrow inlet at the rear end and a wide outlet at the front end. There is a partition block in the material passage between the inlet and the discharge port to divide the material passage into two side-by-side parts.

The rear section of the partition block extends backward from the feed inlet, and its horizontal section is arc-shaped; the middle section of the partition block is located in the material channel, and its horizontal section is triangular; the front section of the partition block extends forward from the material channel, And extend out the front end of the discharge port, its horizontal section is linear.

A partition block is arranged in the casting nozzle, so that two casting-rolling blanks with a narrow width can be produced on the same casting-rolling equipment at the same time, which improves equipment utilization and reduces manufacturing costs. At the same time, the shape of the partition block allows the material to enter the roll smoothly, ensuring the reliability of production and operation.