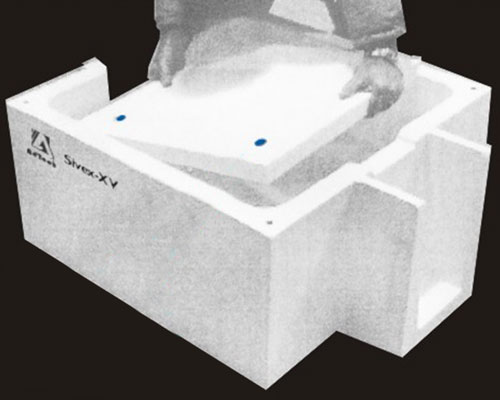

Tubular filter device was first proposed in the United States in 1960, and later developed and applied by Japan. In Japan and South Korea, tubular filter devices are mainly used as the standard configuration for producing double zero aluminum foil. The tubular filter device is a filter tube made of high-quality lead oxide sintered with an inlet and an outlet (a set of several tubular filters). The fixing plates at both ends are made of silicon nitride precast refractory lining and the lid is equipped with Rod-shaped heater, ceramic board and calcium silicate board insulation layer, and a plug to drain the remaining aluminum liquid. The liquid aluminum with only one end open on the filter tube is filtered out from the outside of the tube through the inside.

Tubular Filter Device

Advantages

①Large filtration area, slow unit flow rate, high filtration effect.

②The casing is integral, easy to load and unload.

③With the finest filter pore size, it can remove inclusions less than 5um.

④The production of high-end products is beneficial if the process requirements are proper.

Disadvantage

①It is not conducive to frequent replacement of alloy, suitable for single product.

②The heating time for preheating is long, generally 1~2 days.

③The filter tube is made by bonding and firing, and the brittleness is prone to cracks during transportation.

④ High requirements for molten aluminum temperature, slag gas content, and amount of refiner, etc. The filter tube is easy to be blocked.

In order to save the cost of production, ceramic foam filter devices are used when casting slab ingots for rolling or extrusion round ingots for common products. Ceramic foam filter units have been widely used at home and abroad. The deep bed filter device is mainly used when providing raw materials for aluminum foil, PS plate, can material, aviation material, etc. At present, the domestically introduced filter devices are mainly used to provide raw materials for aluminum foil, such as Xinjiang Zhonghe, Henan Shenhuo, etc., foreign countries mainly include Alcoa and Alcan.

The tubular filter structure absorbs the cartridge type and heat exchange technology of the chemical processing industry. After being applied to the aluminum casting industry, when the liquid metal flow rate is constant, the filter area is increased through a larger number of tube components to improve the filter efficiency. Mainly to meet the quality requirements of high-precision products such as airplanes, automobiles, disks, aluminum foil, and cans. Only a few domestic manufacturers use it. Such as Shan Dong Nanshan, Guangxi Nannan, etc., in Japan, South Korea, mainly use tubular filters.