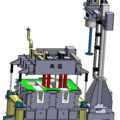

The molten aluminium degasser is a degassing and purification product. It uses the most advanced control technology, a man-machine interface, and is controlled by a PLC computer program. According to the flow rate and purification degree of the alloy, the purity of the aluminum melt purification is guaranteed. To ensure its precise positioning, two hydraulic cylinders are used as lifting devices to control the vertical upward movement of the graphite rotor and the U-shaped silicon carbide heater heating system. It moves down and can rotate 90° horizontally. The hydraulic system is relatively stable and the positioning is accurate.

The online degassing equipment mainly processes molten aluminum containing a certain amount of hydrogen and other residues (alkali metals, slag inclusions), which will be removed after being processed by the degassing equipment. High degassing rate, low operating cost, reliable operation, simple maintenance and other advantages.

The aluminium degasser lining has good thermal shock resistance, thermal shock resistance and low thermal expansion coefficient. It maintains a stable appearance at working temperature and has excellent non-wetting properties with aluminum. After the aluminum liquid flows, it will not stick to the aluminum and is easy to clean. Good durability, good surface strength, resistance to corrosion and corrosion of liquid aluminum, no moisture absorption, no vaporization of liquid aluminum, lower density than aluminum, good chemical stability and no reaction with aluminum at working temperature.

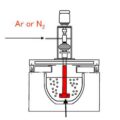

The processing principle of the online degassing equipment is the air flotation principle. The process gas (inert gas or a mixture of inert gas and chlorine) is injected into the melt through the rotor and broken into uniformly dispersed tiny bubbles through the rotor, which rise to the surface of the melt.

A degassing device is installed between the holding furnace and the casting machine, and the nitrogen blown into the aluminum alloy melt is chopped by the rotating graphite rotor in the degassing treatment tank. A large number of dispersed bubbles are formed so that the aluminum alloy liquid and nitrogen are completely contacted in the processing tank. According to the principle of air pressure difference and surface adsorption, the bubbles absorb the hydrogen in the melt in the melt and absorb the oxidized slag (large slag with collision). It becomes smaller by means of radial interception) and then rises to the surface of the melt to form scum.