Molten metal filtration with ceramic filter can be performed at any stage after the aluminum raw material is melted and refined in the furnace and before the molten Al is supplied to the mold for casting. Molten metal filtration with ceramic foam filter improves inclusion removal and filter life. In other words, the filter can […]

Tag Archives: Cff Filter Box

Advanced metal melt filtering devices are used in the melting and casting workshops of aluminum processing plants, mainly including CFF filtering devices, deep bed filtering devices, and tubular filtering devices. Ceramic foam filter filtration and deep bed filtration belong to internal filtration, while tubular filtration belongs to the double capture of impurities on the surface […]

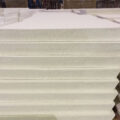

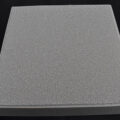

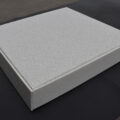

The molten metal filtering device can prevent the molten metal from solidifying and clogging due to the oxide film entering the surface of the molten metal or the temperature drop of the filter medium itself. The molten metal filter medium is made of porous ceramic material in the shape of a flat plate. This filter […]

CFF Filtering System consists of a heater cover, an electrical device, and ceramic foam filter box. The on-line filter box contains molten metal and is designed to support the ceramic foam filter and provide metal circulation space. The CFF filter box has two chambers for capturing impurities in the molten metal, and one metal inlet and […]

The oxide film and impurity particles suspended in the molten aluminum are difficult to completely remove in a furnace with a wide open surface. The effect of applying the flux with the powder spraying machine is better, but it is still difficult to achieve the purpose of comprehensively purifying the molten aluminum. Therefore, in addition […]

Aluminium is melted in a melting furnace before further processing and almost always filtration is required. The ceramic foam filter filtration method depends on the casting technique used or the treatment of the molten aluminum. It is generally believed that it is possible and beneficial only when sufficient amounts of metal are used. However, filters […]

Aluminum filtration equipment is designed for getting clean molten aluminum. Molten metal cleanliness is one of the major challenges for most foundries. They have to produce slabs containing enough hydrogen, alkali metals (mainly sodium) and inclusions to make their final products suitable for their end use. This is particularly important when the slab is rolled into […]

The aluminum liquid filtering device is composed of an aluminum liquid filter box and a filter plate. The metal aluminum liquid enters from one side of the filter box. After impurities are filtered by the filter plate, the cleaner aluminum liquid flows out from the other side of the filter box. The disadvantage is that […]

With the progress of society, aluminum products are more and more widely used in social and industrial applications, and higher requirements are placed on aluminum liquid filtration equipment. The aluminum liquid filter box is a commonly used equipment in the manufacturing process of aluminum products, and in the aluminum casting process, the purity of the […]

Iron is the main impurity element in aluminum alloys. In the 6063 aluminum bar, the national standard stipulates that it is not more than 0.35. If a first-grade industrial aluminum ingot is used in production, the general iron content can be controlled below 0.25. However, if in order to reduce production costs, a large amount […]

- 1

- 2

Contact Us

TEL: +86 371-87095601

E-mail: sales@alalloycasting.com

About Us

ADTECH is one pioneer following by the International Enterprise, who keeps focusing on the manufacture of the metallurgical material.

Address

NO.39 GARDEN ROAD, JINSHUI DISTRICT

ZHENGZHOU, HENAN, CHINA

TEL: +86 371-87095601

E-mail: sales@alalloycasting.com