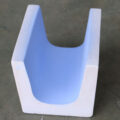

The installation of aluminum liquid filtering system depends on the type of ceramic foam filter sealing liner. When using the ceramic foam filter with expanded cotton edge sealing liner, after placing the filter plate, just lightly press it. When the filter plate is preheated, the sealing liner is heated and expanded to fill the gap between the filter plate and the filter box, and the filter plate is pressed tightly. Do not press too tightly on the filter plate with this kind of sealing lining, otherwise, when the filter plate is heated, the stress generated by the expansion of the sealing village will crack or break the filter plate. Use ceramic foam filter with fiber cotton edge sealing liner, you should apply enough pressure. Place your palms on the four corners of the filter plate so that the applied force is evenly distributed across the filter plate.

Preheat the ceramic foam filter plate before use to remove moisture in the filter plate and filter box, reduce thermal shock, and protect the filter plate and the refractory material of the filter box from damage. You can use an electric heating cover or put a burner in the outlet channel of the filter box for preheating, and the filter plate can be preheated to slightly higher than 370°C. Gas burners have been widely used due to their simple structure and convenient use. However, such burners tend to overheat the filter plate and the refractory material of the filter box. Overheating will damage the filter plate, and also damage the refractory materials of the filter box, shorten the service life of the filter box, and make the filter box unable to be cleaned. Therefore, overheating should be avoided.

In order for the metal melt to pass through the aluminum liquid filtering system, the surface tension of the oxide film on the surface of the melt must be overcome, and there must be enough metal indenter to infuse the filter plate.

Follow the steps below to ensure that the filter plate is infused.

(1) Fill the filter box at an appropriate flow rate without large vortex, which can reduce the generation and inclusion of inclusions. Excessive inclusions can greatly reduce the ability of the filter plate to capture inclusions.

(2) Let the filter plate infuse in a natural state, do not beat, shake and interfere with the filter box. Any disturbance will result in local perfusion, which will reduce the filtering effect and the ability to trap inclusions.

(3) A baffle is set on the flow trough between the filter box and the casting machine, and the molten metal is first poured into the filter plate and then filled with the flow trough in front of the dam, and then the baffle dam is opened to start casting. This method exposes the filter plate to the full pressure head again, thus ensuring 100% perfusion of the filter plate, and also provides a rapid flow of hot metal that is conducive to the beginning of casting.