In many industrial production processes, especially metal smelting, various refining agents are added to improve the performance advantages of products. Regardless of the pharmaceutical industry or the metal industry, refining agents are one of the common fluxes products, mainly white powder or granules, which are prepared by a variety of inorganic salt treatments in a […]

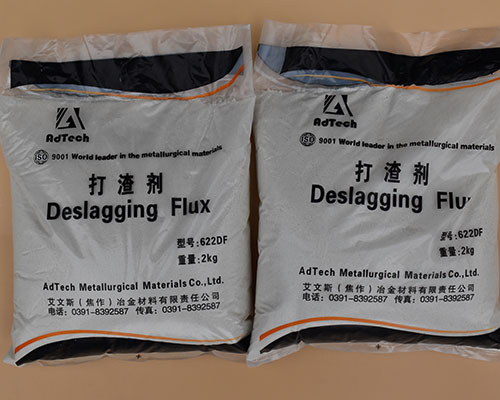

In the era of continuous innovation in casting technology, new casting equipment and casting processes are constantly being used. Aluminum slagging agent and large-scale automatic casting molding lines have been quickly promoted and used in aluminum foundry. At the same time, the requirements for smelting efficiency, pouring time, etc., which affect casting grades, elongation, and […]

The aluminum drossing fluxes are used in production actually has three functions of adsorption, dissolution, and combination of slag-making. The slag-removing effect is dependent on refining temperature, time, and flux properties. Refining Temperature When the aluminum deslagging flux is constant, the main factor slag-removing affecting is temperature. Increasing the refining temperature is also beneficial for […]

Alu refining flux is made of a variety of salt compounds by a special process, using a refining powder sprayer with nitrogen as a carrier, and evenly spraying it into the aluminum liquid, thereby achieving double purification of the melt by gas and flux. This product is in aluminum It is widely used in the […]

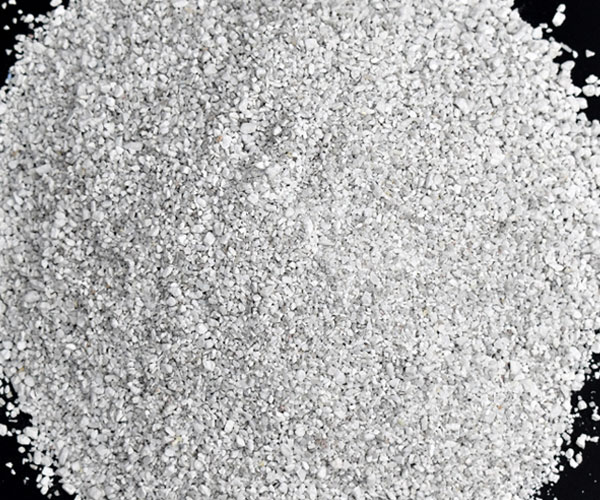

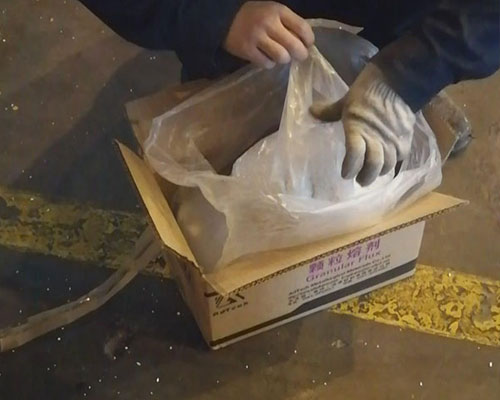

Aluminium Granular Flux reacts peacefully in aluminum water, does not burn violently and generates a lot of smoke, and has a low moisture content, which can create a good working environment. The product is granular (0.82-3.15mm) and has a larger contact area with the aluminum liquid than the bulk refining agent. The effect of degassing […]

Fluxes for aluminum foundry divide into cover flux, drossing flux, cleaning flux, and degassing flux, which is used for molten aluminum refining. Aluminum is very active chemically. A hard film or skin of aluminum oxide will quickly form on all newly exposed surfaces, especially in the molten state. Adding scrap or ingots to the melt, […]

The use of a chlorine-containing reactive fluxes, for the purpose of the removal of alkali elements (Na, Ca, K, Li), is a well established practice in the treatment of molten aluminum. Under equilibrium conditions, the respective chlorides of these elements are produced as reaction products. With the exception of LiCl, all of these halide salts, […]

AdTech provides a molten Al refining agent, which can reduce or remove gas and inclusions at a high level during refining, and there is no problem of flux residue in it. When the refined flux is added to the molten aluminum alloy, it is an alloy obtained by refining the aluminum raw material by melting. […]

AdTech molten aluminium refining agent is a flux that reduces the alumina entrained in aluminum castings. Coat a layer of flux on the surface of the molten aluminum. Subsequently, the charge is melted in a furnace to form a molten pool of liquid aluminum suitable for casting. The flux layer removes the naturally occurring oxide […]

The covering fluxes are used to cover the melt. These fluxes composed of salt compounds will form a liquid at the normal melting temperature of aluminum, and they provide a molten barrier “blanket” on the metal surface to protect it from oxidation and hydrogen adsorption. The covering flux is mainly a mixture of NaCl and […]