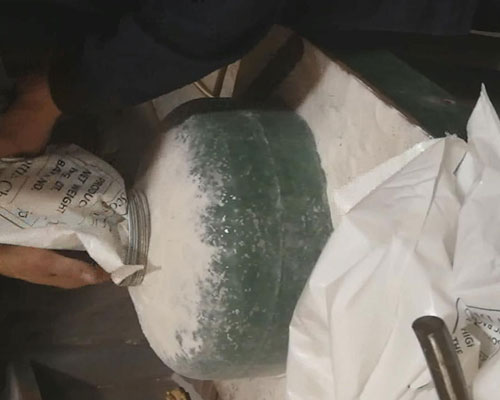

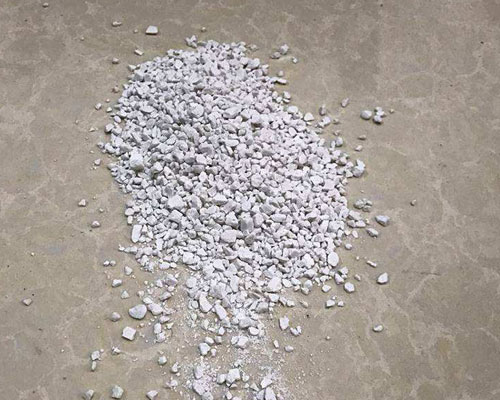

The aluminium refining flux is white powder and granular. It is mixed according to a certain proportion after the drying of various inorganic salts. It plays an important role in the process of smelting aluminium. What is the role of the specific aluminium refining agent? Aluminium refining flux is mainly used to remove the hydrogen […]

In the production, during the solidification of aluminum alloy solution, hydrogen atoms in the aluminum alloy solution spontaneously form hydrogen molecules, and hydrogen molecules and non-metallic inclusions form bubbles during solidification, and inclusions are the main cause of defects in aluminum alloy castings. The reason is that most of the impurities and gases in the […]

The granular refining flux has a good effect of removing slag and impurities in the aluminum melt. The principle of slag removal is: when the Non-Sodium Granulated Flux is sprayed into the aluminum melt by inert gas, the solid particles can quickly melt into droplets. Because the density of these droplets is less than that […]

It can be seen from the principle of casting and rolling that the entire gating system is a “U”-shaped connector. The level of the liquid metal in the front tank determines the metal pressure at the mouth of the feed nozzle. The liquid level is not well controlled, and the casting process cannot proceed normally. […]

Aluminum silicate caster tip, also known as the casting nozzle, is a key component that directly transports and distributes the liquid metal to the casting roll during the continuous casting and rolling process. It is composed of upper and lower plate, several spacers, and side ears. Material requirements of the feed nozzle. It is a […]

The structure of the feed nozzle is diverse, which can be selected according to the respective process and equipment conditions. The open size of the gasket can change with the change of the plate width. During processing, try not to have sharp corners and dead corners in each runner and block. When assembling the gasket […]

With the advancement of aluminum alloy processing technology and the development of aluminum alloy agent purification technology, the preparation of flux and its performance requirements show some new characteristics, which not only put forward higher requirements for the purification effect of the flux, but also the purification effect of the flux. Put forward higher requirements. […]

The molten metal CFF filtration grade (blended) is between 20 and 80 ppi, but the most commonly used is 30ppi.50ppi. The layout of molten metal CFF includes single-layer filtration and double-layer filtration. Advantages of ceramic foam filter 1. Low cost. 2. The alloy varieties are easy to replace. 3. Easy installation. 4. Roughly small and […]

The aluminum cast filter is an iconic development of Adtech. This means that Russia’s most famous aluminum industry giant has approved and used our products. According to Rusal Aluminium, since the advent of ceramic foam filter (CFF) in the 1970s, it has been widely used in aluminum due to its high porosity, large adsorption area, […]

The ceramic foam filter in China is not expensive for European aluminum plants, and the quality is stable. Swedish Aluminum said that ceramic foam filter in China plants can provide a stable supply cycle. Swedish Aluminum Corporation said that ceramic foam filters are very important for the purification of aluminum melt. The so-called purification treatment […]