Tapout Cones uses the loose cotton formed by wet vacuum suction according to the user’s design requirements, which is dried and calcined to produce high temperature aluminum water plugs with different bulk densities, specifications, models and performances. In addition to satisfying users’ various complex heat dissipation requirements, each Tapout Cones product is also made with […]

Aluminum tap cones are mainly made of high-grade silicate fibers and other formulas through vacuum forming. The plugging sleeve is used in aluminum smelting furnaces, static furnaces and other aluminum tapping furnaces. It is suitable for aluminum melting furnace, refining furnace, static furnace and tapping furnace. The mouth insulation makes the aluminum and aluminum alloy […]

The distribution level of the nozzle determines the distribution effect of the aluminum melt in the cavity of the aluminium silicate caster tip, and plays a decisive role in the uniformity of the alloy chemical composition, flow field and temperature field in the nozzle. The 8079 aluminum alloy cast-rolled sheet has a large surface width, […]

At present, using N2 and Ar gas as a carrier, adding a small amount of pollution-free refining agent, using a single tube, porous or rotary degassing machines to purify aluminum liquid, is an advanced refining technology, which has been widely used in industrialized countries. According to the dynamic theory, there is a certain relationship between […]

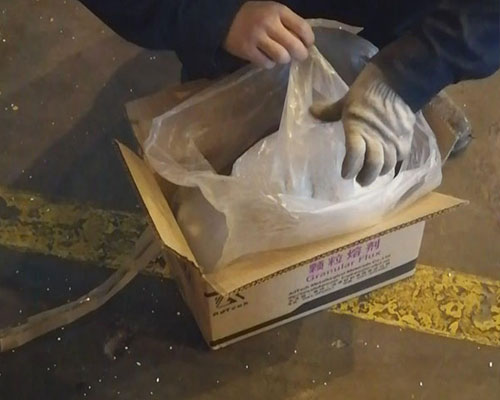

The main components of aluminum alloy refining agents are chloride salts, fluoride salts and other compounds. After proper heat treatment and sieving, the particle size is uniform, which is beneficial for the carrier gas (N2 or under the action of Ar) in the refining tank to uniformly enter the lower layer of molten aluminum through […]

The aluminum melt online processing device is mainly composed of an online degassing device, a filtering device, an electric control system, a hydraulic system, a refined gas control cabinet, and a connecting ceramic launder (between the degassing unit and the filtering unit). Equipment Function (1) The online degassing device is used for on-line degassing and slag […]

The aluminum melt coming out of the furnace contains certain amounts of impurities (hydrogen, alkaline metals, slag inclusions), and these impurities will be removed in the degassing purification equipment. AdTech dual-rotor degassing unit blows out inert gas through the rotor, and generates fine bubbles by means of a rotating nozzle. The rotating nozzle is made […]

Aluminum Casting Flux is used in a variety of aluminum alloy melts, and can be used for pure aluminum smelting, refining and slagging. When using, just sprinkle the refining agent on the surface, then quickly dissolve it in the aluminum liquid, and then fully stir it. If a jet is used, it is best to […]

After the melt is purified by the on-line degassing device, there are still some inclusions in the molten aluminum that cannot be eliminated, and one step of effective filtering measures must be taken to remove the tiny inclusions in the molten aluminum. Ceramic foam is a new type of ceramic filter material developed in recent […]

Alu Aluminium Cff can reduce the gas and inclusions in the casting, reduce the turbulence of the molten metal, reduce the surface defects of the casting, and significantly reduce the rejection rate of the casting. Improve the compression and sealing of castings, increase the elongation and tensile strength of the castings, improve the surface finish […]