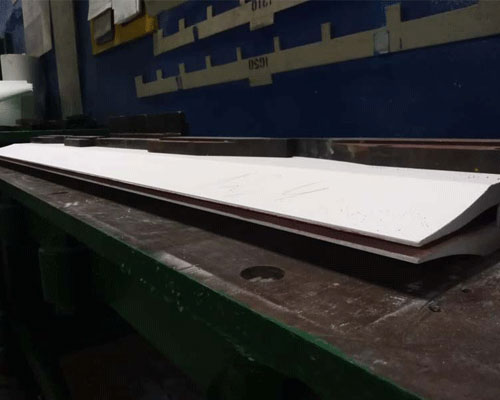

The ceramic filter plate is an energy-saving and environmentally friendly product, which is widely used in the dehydration process of metal ore operations such as iron, gold, silver and copper. It plays a vital role in energy-saving and emission reduction. For use in most cases, the dry material is generally left for the ceramic filter […]

SEO

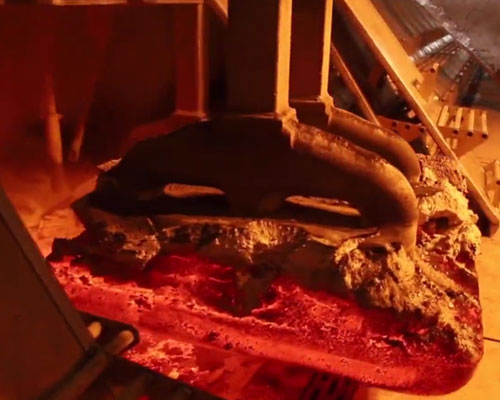

In the production of aluminum castings, the aluminum ingot melts into molten aluminum liquid at high temperature in the furnace. Due to the existence of high temperature gas and other impurities in the furnace, the aluminum liquid needs to be pretreated before the aluminum liquid is introduced into the die casting mold. The molten aluminum […]

The aluminum liquid filtering device is composed of an aluminum liquid filter box and a filter plate. The metal aluminum liquid enters from one side of the filter box. After impurities are filtered by the filter plate, the cleaner aluminum liquid flows out from the other side of the filter box. The disadvantage is that […]

With the progress of society, aluminum products are more and more widely used in social and industrial applications, and higher requirements are placed on aluminum liquid filtration equipment. The aluminum liquid filter box is a commonly used equipment in the manufacturing process of aluminum products, and in the aluminum casting process, the purity of the […]

The Aluminum Silicate Ceramic Caster Tip is a key component for directly distributing and conveying aluminum liquid to the roll gap during the casting and rolling process. The rationality and practicability of the structure and the selection of the material of the casting nozzle are carried out normally to stabilize the various process parameters and […]

Vacuum Refractory Shapes, also known as aluminum silicate plugs, insulation tap out cones, and refractory fiber cones. The aluminum silicate plug is suitable for the heat insulation and sealing of the outlets of aluminum smelting furnaces, refining furnaces, stationary furnaces, etc., making the aluminum alloy casting process more convenient and safer. The ceramic fiber shaped […]

Ceramic fiber filtration technology is one of the faster-developing filtration technologies in recent years. Compared with the traditional granular filter material, the specific surface area of the fiber filter material is larger, has a larger interface adsorption and can retain suspended matter, and the filtration effect is good. Compared with organic fiber filters, ceramic fibers […]

The workpieces produced by aluminum alloy die casting are often scrapped due to the existence of pores. There are many reasons for the occurrence of Pore Defects in Aluminum Casting. When solving this product quality problem, it is often impossible to start. How to quickly and correctly take measures to reduce the scrap rate caused […]

Porosity in aluminum alloy often occurs in the upper part of the casting and often occurs on the surface of the protruding part of the casting. The hidden pores inside the casting can be seen through X-rays. The degassing process in aluminum casting can solve the porosity. Causes of Porosity in aluminum Alloy The pouring […]

When aluminum alloy is smelted, the refining and degassing process is needed to dissolve the hydrogen into the aluminum liquid, which strengthens the control of the aluminum alloy inhalation during the melting process. Production practice shows that the hydrogen absorption of aluminum liquid is carried out on the surface, which is not only related to […]