The aluminium degassing box adopts a double-channel sealed design, which prevents oxygen in the outside air from entering the degassing box, contacting aluminum liquid to cause oxidation slagging and secondary permeation of hydrogen, which greatly improves the degassing efficiency. During this process, the heating chamber will keep the molten aluminum flowing through the aluminium degassing […]

AdTech box type online degassing equipment is a high-end online degassing equipment, the equipment adopts PLC + touch screen control, with hydraulic lifting, hydraulic rotation, automatic degassing, aluminum liquid temperature control, and other functions. The box type online degassing equipment is installed close to the launder. The launder is designed with an aluminum liquid inlet […]

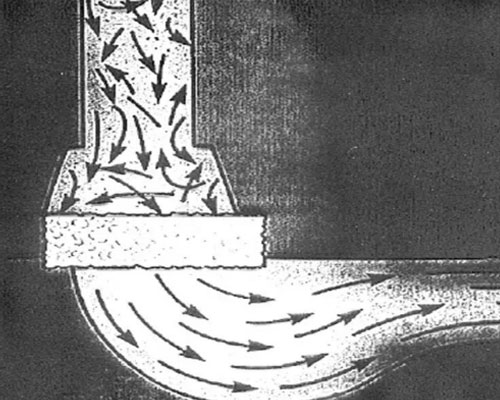

Ceramic foam filters for metal purification are filtered in two modes: cake filtration, where suspended particles are larger than the pore size of the filter, and are deposited at the entrance of the filter, forming a cake that is constantly increasing in thickness, forming a practical filter medium. Deep filtration, in which the size of […]

The online aluminium degassing system is mainly used in the processing of molten aluminum, and it is expected to remove gases and other impurities from the molten aluminum before further processing and depending on the specific process. If hydrogen remains in the aluminum during the casting process, the escape of hydrogen from the solution may […]

The purification of molten metal plays an important role in improving the mechanical properties of castings. At present, the filtering device used to purify the molten metal is mainly a ceramic foam filter, which can effectively intercept harmful impurities in the molten metal, and convert the metal liquid from turbulent flow to laminar flow, and […]

AdTech high-temperature refractory cone is made of high-aluminum fiber and made by vacuum forming process, with a yield rate of up to 99%. It is also called Ceramic Cone, Tap Out Cone, Alumina Silicate Tap Cone. AdTech high-temperature plugs have uniform mass distribution, higher hardness than ordinary plugs, tight plugging, non-stick aluminum and no slagging, and […]

The key to the degassing of molten aluminum is the quality of degassing, and in order to minimize the hydrogen in the molten aluminum, it is necessary to provide a method for degassing the molten aluminum, which can better remove the hydrogen in the molten aluminum. Because the performance of aluminum alloy wire is incomparable […]

Online purification for aluminum foil can effectively remove the hydrogen content in aluminum alloy, and can ensure that the cast-rolled billet used to produce ultra-thin aluminum foil meets the quality requirements. In the aluminum foil processing industry, the processing of ultra-thin aluminum foil is hard. However, it is more difficult to process ultra-thin aluminum foil […]

At present, the world’s aluminum rod continuous casting production lines with relatively advanced technology, better product quality, and many users mainly include the production line of the South Line Company of the United States, the production line of the Italian Continuous Company, and the production line of the French Company. Our company mainly provides online […]

The aluminum water refining can reduce the gas and certain impurities, and meet certain properties. Aluminum water refining has two stages: furnace refining and online refining. The former is preliminary and relatively rough refining. The latter is carried out during the flow of molten aluminum from the furnace to casting machine. Flux refining mainly involves […]