In a traditional filter device, the molten metal flows down into the filter medium. During switching from one smelting furnace to another smelting furnace, when the flow of molten metal from the furnace into the filter device is stopped, the molten metal remaining in the filter device flows away through the filter medium. For this reason, the filter medium is exposed to the ambient air, and the aluminum oxide film remains, so the filter medium may be clogged.

Conventional molten metal filtering devices, especially those used to filter molten metal produced by multiple continuously operating smelting furnaces, do not fully consider the solidification of molten metal in the filter medium, and the problem is that during the maintenance of the device ongoing. Switching from one smelting furnace to another smelting furnace, and the problem of damage to the filter medium due to this solidification.

Moreover, in the conventional filter device, when the used filter medium is exposed to the air and cooled to a lower temperature, it must be replaced with a new filter medium. When a conventional filter device is actually used, the filter medium incorporated therein is not easily changed under the high temperature at which the device operates.

Batch operations include the steps of smelting metal, especially aluminum in the form of ingots, in a furnace, filtering the produced molten metal with a filter medium, and charging the filtered molten metal to produce slabs or billets, and it has been widely accepted. Recently, in order to increase the productivity of this operation and ensure energy saving, efforts are being made to shorten the interval between continuous batch operations of the smelting furnace.

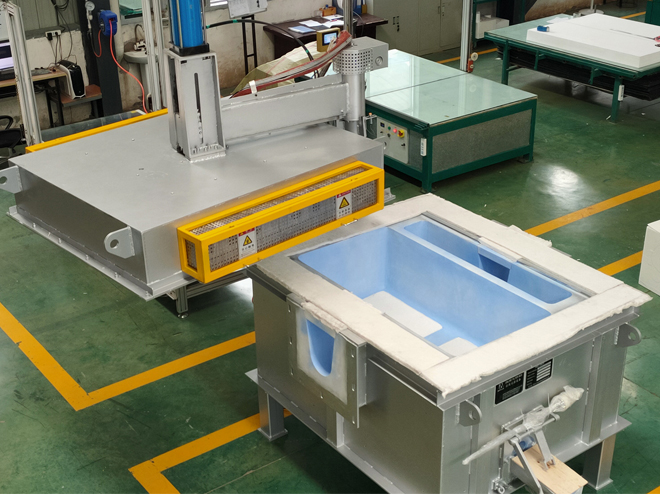

AdTech online plate filtering equipment shortens the interval between continuous batch operations of the smelting furnace. On-line filtration equipment is mainly used for continuous casting of molten aluminum, which removes the impurities in the molten aluminum, and also reduces the secondary pollution of the molten aluminum. It replaces the high-cost ceramic tubular filtering unit and ordinary filtering unit.