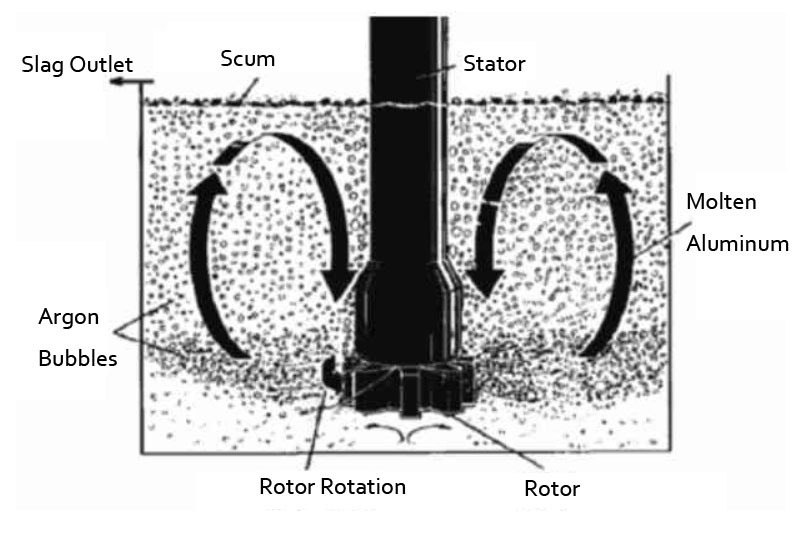

In order to overcome the shortcomings of the single-pipe blowing method, such as the small area of action and the difficulty of controlling the bubble size, a rotary blow method with a porous blowing head was developed. The structure of the blowing head can be varied, but the purpose is only one, that is, to uniformly form a large number of small bubbles in the melt.

The rotary blow method using shearing action, its structure is composed of static and moving plates. The inert gas flows downwards from the upper part, changing the direction between the stationary plate and the moving plate to flow radially. Due to its sucking action, the melt flows downward and upward from the upper and lower tooth grooves of the blowing head, and the two meet between the static plate and the moving plate. Under the action of shear force, a relatively uniform gas-liquid flow is formed, and a large number of uniform and fine bubbles are formed when the gas-liquid leaves the blowing head. These bubbles move in the radial direction, and then move upward to escape. At the same time, the melt also moves in circulation.

Utilizing centrifugal force, the nozzle has many small holes distributed along the radial direction, and there are many oblique small holes connected to the radial small holes and formed at a certain angle. The inert gas flows downward from the upper part, and then changes direction to flow radially. Due to the centrifugal force, the melt flows from the lower part of the blowing head along the oblique small holes obliquely upward, and the two meet at the intersection to form a more uniform gas-liquid flow. When the gas-liquid flow leaves the small hole, it will encounter the boss of the blowing head and break it into a large number of uniform and small bubbles. These airs move and then move upward, and at the same time, the melt also moves in circulation. This method has a good molten aluminum degassing effect, no pollution, and has been widely used in industry.