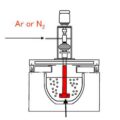

In the rotary method of the aluminum liquid degasser, an inert or chemically inactive gas (Argon, Nitrogen) is purged through a rotary shaft and a rotor. The energy of the rotating shaft causes the formation of a large number of fine bubbles offering a very high surface/volume ratio. The large specific surface area promotes rapid […]

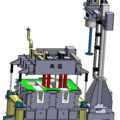

The molten aluminum degassing equipment adopts compact furnace design. In the degassing box, a rotating nozzle is used to degass the molten aluminum, and convection is formed in the box so that small bubbles can completely diffuse into the molten aluminum. At the same time, the sealing design is adopted to prevent the secondary pollution […]

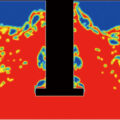

Degassing process in aluminum can be divided into two situations: one is the hydrogen removal process that can form hydrogen bubbles; the other is the hydrogen removal process that cannot form hydrogen bubbles. The degassing process in aluminum that can form hydrogen bubbles can be roughly divided into three stages: first, the formation of bubbles, […]

Rotary degassing purification method is a kind of bubble floatation method, and it is also the most widely used aluminum alloy melt purification method. Rotary blowing degassing purification method by degassing unit is to pass inert gas in aluminum alloy melt in the aluminum alloy melt. It is broken and ejected at high speed when […]

Aluminum Liquid Purification is important, because the electrolytic aluminum solution contains a large number of non-metallic inclusions and carbides, nitrides, and sulfides. When the electrolytic aluminum liquid directly enters the melting pool of the smelting furnace, it is easy to adhere to the refractory lining of the smelting furnace, and is closely integrated with the […]

Aluminium degassing machine most notable feature is the graphite stator and graphite rod/rotor structure. The graphite stator does not rotate in the molten aluminum and protects the graphite rod/rotor assembly. The graphite rod and the graphite rotor are assembled together to stir the aluminum water. The inert gas passes through the gap between the stator […]

Molten aluminum is extremely reactive, so when it comes in contact with moist air or wet tools, the water decomposes to release hydrogen in the melt. Excessive quantities of this dissolved gas have a well-documented detrimental effect on the mechanical properties of the final aluminum castings. What is also well known to anyone making castings […]

There are two ways to remove these impurities in the degassing system of the aluminum plant. One is to use refining treatment in the furnace, and the other is to carry out on-line processing on the casting line. It is proved that In Line Degasser is the most improved metallurgical quality of aluminum liquid. In […]

Many aluminum foundries have adopted the Degassing System for Molten Aluminum, In order to guarantee the quality of the final aluminum product, the aluminum melt needs to be purified and degassed. In the aerospace and food processing industries, the production of end products requires high-quality aluminum melts. Aluminum processing requires higher and higher performance for […]