Aluminum Melt Degasser has become an extremely important production process for aluminum alloys. Advanced molten aluminum purification technology is of great significance for ensuring the metallurgical quality of aluminum alloy and improving the final performance of the product.

Aluminum liquid purification equipment is a kind of degassing and purification treatment equipment, which cleans metals by removing physical (hydrogen content), chemicals (alkali metals) and metallurgical (alkali salts and sludge metal intermetallic) impurities. The operation of the molten aluminum purification system is based on the proven principles of high-energy diffusion and chemically driven mass transfer.

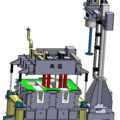

AdTech aluminum purification equipment provides patented gas preheating and other precision functions to optimize molten aluminum refining. This aluminum liquid purifier is also called a degassing bowl, degassing box, degassing device, or molten aluminum refining and degassing equipment.

Aluminum Melt Degasser becomes easily inhaled and oxidized during the casting process. Therefore, gases and various non-metallic inclusions exist to varying degrees in the melting, leading to defects such as the loosening of pores and inclusions.

Significantly reduce the mechanical properties, processing properties, fatigue resistance, chemical resistance, and anode properties of aluminum, and even lead to product scrapping.

In order to reduce the influence of gas and non-metallic inclusions, on the one hand, people have put forward strict requirements on the raw materials and smelting processes of alloy preparation. On the other hand, they are committed to the research and application of advanced melting purification technology.

Before using molten aluminum for casting, hydrogen must be removed from the melt to avoid bubbles in cast aluminum parts. This can be done by using a rotor, rotating in the aluminum melt, and purging the molten aluminum through the shaft with Argon gas. Compared with graphite rotors, silicon nitride rotor shafts and wheels have excellent wear and oxidation resistance. They guarantee a stable high hydrogen removal efficiency and have a long life.