When selecting the composition of the aluminum liquid refining agent, in addition to the physical properties of the refining agent (such as melting point, viscosity, surface tension, density, volatility, etc.), the characteristics of the chemical interaction between the refining agent and the metal and the gaseous medium must also be considered, so that it has […]

When using the fluxes for aluminum refining, the fluxes are pressed into the molten pool with a bell jar, and the volatile bubbles generated by the thermal decomposition of the flux or the chemical reaction with the metal are used to achieve the purpose of dehydrogenation. The more gas produced by the same weight of […]

For aluminum and aluminum alloys, degassing and slagging with flux is an important method. When using flux refining, a large number of dispersed and fine flux droplets are formed in the melt. According to the law of dissolution equilibrium, the atomic hydrogen in the melt is brought to the liquid surface due to the diffusion […]

Aluminum and aluminum alloys are easy to inhale and form inclusions during the smelting and pouring process, which directly affects the quality of their products. The molten aluminum degassing fluxes can significantly reduce the gas content in the molten aluminum, reduce the inclusions in the molten aluminum, reduce the content of harmful elements in the […]

Furnace refining flux is widely used in aluminum foundry. The main goal of aluminum melt purification technology is to continuously improve the purity of the melt, constantly pursue high-efficiency and low-cost purification technology, and meet the development needs of aluminum processing melt purification technology. The inclusions in aluminum and aluminum alloy melts are mainly aluminum […]

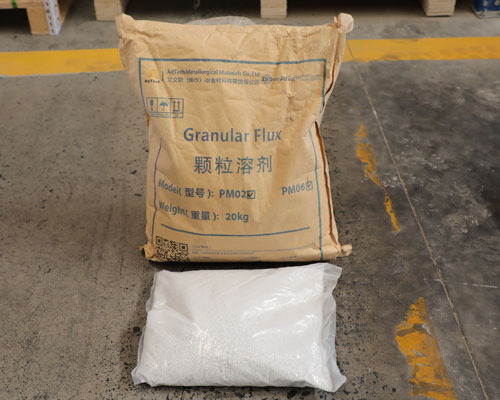

Aluminum Casting Refining Fluxes are an environmentally friendly range of fluxes used for molten metal treatment. Powder fluxes possess certain disadvantages such as dusting during the application, toxic fume emissions. This causes health hazards to the workers and environmental problems. The powder fluxes also pose a problem of inconsistent efficiency due to the morphology of […]

Wall cleaning fluxes help keep crucible and furnace walls above and below the melt line free of oxide build-up. This reduces both alloy wastage and another source of unwanted inclusions. Wall cleaning fluxes soften oxides built upon the furnace walls. Wall cleaning fluxes contain double fluorides (Na2SiF6, Na2AlF6) and an oxidizing agent. The oxidizing agent […]

Aluminum Smelter Refining Fluxes are used in aluminum foundries, so as to reduce the melt oxidation, minimize penetration of the atmospheric hydrogen, absorb non-metallic inclusions suspended in the melt. The melting point of a cover flux is lower than that of aluminum. Cover flux is applied on the surface of molten aluminum where it melts […]

Aluminum Melting Refining Fluxes exist in the form of salt compounds, which are used to purify materials during melting and prevent further oxidation. The quality of the aluminum cast billets largely depends on the cleanliness of the material. Aluminum can be processed in two ways. Raw aluminum is recovered through bauxite extract or recycling. Considering […]

Foundries Refining Fluxes are dust-free during use and emit low smoke during use. Compared with powdered flux, granular flux can be used in a reduced amount. Foundries Refining Fluxes remove non-metallic inclusions, the dry ash-like slag produced is easily separated from the liquid metal. Therefore, slag skimming is promoted, and metal loss due to aluminum […]