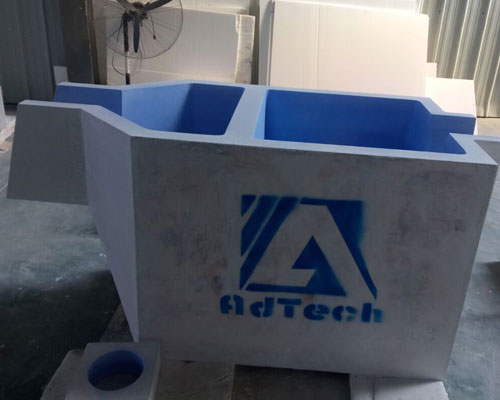

We provide universal 12-inch, 15-inch, 17-inch, 20-inch, 23-inch single-chamber and dual-chamber filter boxes for molten aluminum filtration, and can also make filter products with special size and shape requirements according to customer requirements.

Filter Boxes for Molten Aluminum are made of imported high-strength castable as a whole, which have the characteristics of high strength, good thermal insulation performance, resistance to aluminum melt erosion, non-stick aluminum, and usually does not chemically react with aluminum. The normal service life is more than 18 months (except for high magnesium alloys). The high-quality imported thermal insulation board is filled between the inner lining and the iron shell of the filtering box, which has good thermal insulation effect and sufficient supporting strength.

The filter box and the lining material are molten silicon, which is characterized by low thermal and cold shrinkage rate, and the molten silicon has a very good ability to resist thermal shock. its service life. The “microporous thermal insulation material” is used in the process, and the high-efficiency thermal insulation material makes the surface temperature of the steel structure low and the deformation of the lining small after continuous use of the filter box.

The temperature loss of the covered launder is 0.8°C per meter, and the temperature loss of the uncapped launder is 3°C per meter. The service life of the launder is 200,000 tons. The surface temperature of the filter box is less than 50 ℃, the filter box can be guaranteed to use 80,000 tons, and the service life is about one year to one and a half years. Controlling heat loss is very important in aluminum melting and casting. It can not only reduce the temperature of molten aluminum, save energy, but also easily control the quality of alloys that are very sensitive to temperature. The lining of the filter box of molten silicon has been sintered and dehydrated at 800°C before leaving the factory, and there is no need to consider drying and dehydration before use. The filter equipment is customized according to the needs, and its lining has the characteristics of high hardness, low expansion coefficient, good thermal insulation effect, and strong anti-wear and anti-corrosion performance.

Using fused silica-based castables, the filter box has the characteristics of smooth and delicate working surface, non-stick aluminum, thermal shock resistance and anti-collision.