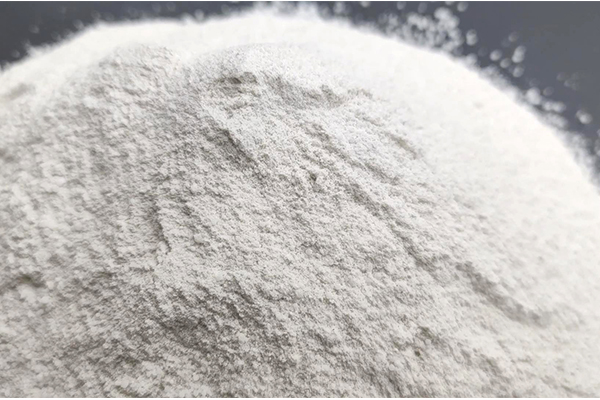

Refine Agent is an important part of the molten aluminum refining process with the addition of aluminum alloy reheating material. It removes the gas and slag in the molten aluminum, and improves the melting process of the aluminum alloy to improve the purity of the molten aluminum.

Oxidation inclusions seriously affect the purity of molten aluminum, causing defects such as bubbles, pores, slag inclusions, and shrinkage in castings, which directly affect the performance of aluminum and aluminum alloy materials.

In the process of aluminum alloy casting, the process steps of feeding, refining, slag removal, standing, and casting are usually carried out. The quality of the final aluminum alloy product depends on the gas content and impurity content in the aluminum alloy and the size of the grain size.

Refine Agent removes impurities such as gas and iron in molten aluminum, and the process of purifying molten aluminum occupies an important position in the production process of aluminum alloy.

The prior art adopts one-step refining, and the process control of refining and the selection of refining agents are particularly critical for the removal of impurities. Incomplete degassing and slagging will often lead to loose aluminum alloy ingots, slag inclusion defects, and lower product qualification rate.

How to fully reduce the hydrogen content in the molten aluminum and further remove the iron-containing impurities in the molten aluminum to obtain high-quality aluminum alloy products is a problem that needs to be solved urgently.

Adtech provides a kind of flux purification technology in the molten aluminum melting furnace. The technology includes two refining and three times slagging technology.

The first refining is to adjust the temperature at 600-700 degrees, add refining agent, and react for 10-30 minutes.

The second refining is to adjust the temperature to 710-800 degrees, add refining agent, and react for 10-20 minutes.

Among them, the refining agent is added before refining, and during the refining process, powder spraying is used in the furnace for refining, the powder spraying machine is used to spray the refining agent into the molten aluminum in the furnace, and argon gas is introduced for degassing.

Refine Agent purification technology improves the cleanliness of electrolytic aluminum liquid, so that the hydrogen content in the processed aluminum liquid is less than 0.125ml/100gAl, and the slag removal rate reaches over 85%, which reduces the looseness and slag inclusion problems caused by aluminum alloy ingots. , Which greatly improves the product qualification rate.