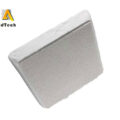

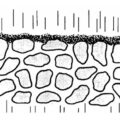

Porous ceramic filter is a porous medium with a three-dimensional through-network structure. It has good chemical stability, high specific strength, high-temperature resistance, thermal shock resistance, and a large specific surface area. It is widely used in the filtration and purification of high-temperature melts in the metallurgical industry. Its filtration The purification mechanism is mainly manifested […]

Product application of filter box: It is suitable for casting occasions using a mesh porous ceramic filter. Product advantages of the filter box: 1. It can be used directly at room temperature without worrying about thermal shock. 2. No thermal expansion, and low thermal conductivity. 3. It can float in aluminum, reducing the possibility of […]

Adtech specializes in the production of porous ceramic filter, which filters impurities in molten aluminum. Contents 1. Gas in molten aluminum 2. How hydrogen is produced in molten aluminum 3. Effect of gas on aluminum ingot 4. Source of inclusions 5. Interaction between inclusions and hydrogen 1. Gas in molten aluminum The gas in molten […]

Aluminum water porous ceramic filter product application: The aluminum-water porous ceramic filter adopts a three-dimensional network structure and an organic foam body connected to pores as a carrier, and invades it into a thixotropic alumina material slurry, and adopts a square correction center distance automatic extrusion process to make the slurry uniform It is coated […]

Applied Research on Shotcrete Technology of Alumina Foam Ceramic Filter Plate 1 Prefacee Foam ceramic is a kind of three-dimensional space grid structure with a high air-void ratio (80% – 90%) porous ceramics, due to their low density, high strength, and high resistance Temperature, corrosion resistance, and good filtration and adsorption. Therefore, it is widely […]

“The aluminum extraction process“. Since the advent of the foam ceramic filter plate technology in the 1970s, it has shown great vitality in producing aluminum and aluminum alloy materials. With the development of society, the quality requirements of aluminum products are getting higher and higher, and the application of ceramic filter plates will become more […]

“the purification of aluminium” Hubei Electromechanical Research and Design Institute has been researching foam ceramic filters since 1988

2. Foaming method The foaming process is adding organic or inorganic chemical substances to ceramic components, generating volatile gas through chemical reactions, etc., and then drying and sintering to make”the porous ceramic filter plate” Compared with the foam impregnation process, the foaming process is easier to control the shape, composition, and density of the product, […]

Ceramic Foam Filter Baie Comeau Aluminum is a new type of filter with low density, high porosity and three-dimensional network frame structure. It is widely used in the aluminum processing industry to filter molten aluminum and improve the quality of aluminum. We provide alumina ceramic foam filters for foundries, mainly for filtering aluminum and aluminum […]

As the third-generation filter equipment, ceramic foam filters for molten metal filtration are particularly widely used in metal smelting and casting production. Foam ceramic filters are used in the filtration and purification of molten metal, which has also promoted the rapid development of the domestic metal casting industry, and improved the yield, machining performance and […]