With the continuous development of aluminum alloy materials in various fields of the national economy, higher and higher requirements are put forward for the internal quality of aluminum alloy materials. In the production process, it is necessary to strictly control the chemical composition of the aluminum alloy and the defects of the ingot shrinkage, pores, pores, slag inclusion, etc., because the inherent quality of the processed product is affected by the quality of the ingot. The internal quality of the ingot depends to a large extent on the quality of the melt. Therefore, the aluminum purification technology is very important. According to the existing equipment and process conditions, the control method of the hydrogen content in the aluminum melt is discussed, and the hydrogen content in the aluminum melt is reduced to obtain high-quality ingots.

Aluminum Purification Technology

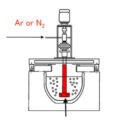

The gas in the aluminum melt is mainly hydrogen (volume fraction is about 60% to 90%), followed by nitrogen, oxygen, carbon monoxide and so on. The purification technology of aluminum melt mainly used for hydrogen removal mainly includes bubble flotation method, vacuum treatment method, ultrasonic treatment method, rare earth hydrogen removal method, etc. The bubble flotation method is widely used because of its simplicity and high efficiency. The process of removing hydrogen by bubble flotation of aluminum melt: the hydrogen atoms dissolved in the aluminum liquid migrate to the surrounding of the bubbles of the purifying agent (argon or nitrogen, etc.), adsorb around the bubbles, and form hydrogen molecules into the bubbles. Finally, as the bubbles float upward, the aluminum melt escapes.

Main equipment: smelting furnace, electromagnetic stirring device, online degassing device, online filtering device, runner system. The electrolytic primary aluminum and materials are smelted and refined in a furnace to obtain a qualified aluminum melt for temperature and composition, and then stand still for processing. The static melt is further purified and cast after being degassed and filtered online through the runner.

The solubility of aluminum when heated to 300°C in air is only 0.001ml/(100g·Al), and solid aluminum basically does not absorb hydrogen. When the aluminum melt enters the casting system, the hydrogen content is basically unchanged. In addition to raw materials, the hydrogen source of the melt is mainly hydrogen absorption during the smelting and casting process. The purpose of using online degassing equipment is to further purify the aluminum melt outside the furnace, and to better remove the gas and slag in the aluminum melt.