The sodium-free refining agent used for aluminum alloy smelting has a significant effect of removing hydrogen during the refining process, and can fully remove oxide inclusions in the melt, and the hot slag recovery is more convenient and the recovery rate is higher. The refining agent can refine the alloy to a certain extent. It […]

In order to further determine the refining efficiency of the granular fused refining agent, an aluminum melting furnace with the same capacity was selected, and the aluminum alloy melt was prepared with electrolytic aluminum liquid and cast into a cast rod. The first furnace aluminum alloy melt is spray-refined with granular refining agent, and the […]

The amount of Aluminum Alloy Casting Flux added to aluminum alloy casting should be determined according to the weight of liquid aluminum, because too much or too little will affect the performance of aluminum alloy, so it must be calculated before adding. When operating the refining agent, the operator should control the refining flow freely […]

Aluminum Smelter Flux is a powdery particle that is in full contact with molten metal. The gas and inclusions in the molten aluminum are brought to the surface of the molten aluminum through physical and chemical effects, and at the same time achieve the purpose of degassing and slag removal, and after a large number […]

Aluminum Alloy Casting Fluxes are used in a variety of aluminum alloy melts, and can be used for pure aluminum smelting, refining, and slagging. When using, just sprinkle the refining agent on the surface, then quickly dissolve it in the aluminum liquid, and then fully stir it. If a jet is used, it is best […]

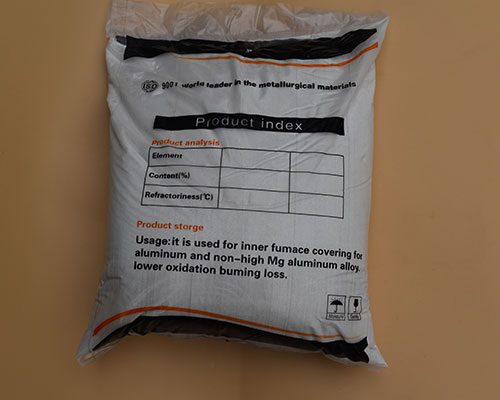

Scrap is usually first charged into the aluminum bath in the furnace, where it is melted. As a result of melting the scrap, a surface layer of oxides, nitrides, and entrained metals called dross are formed. The surface layer is treated with aluminum melting flux to remove scum, and the entrained molten metal is released […]

AdTech Aluminium Drossing Fluxes is white powdery fine particles, the main components are chloride salt and fluoride salt, and other compounds. After proper heating treatment and sieving, the particle size is uniform. It can be carried out with gas in a refining tank. It can also be sprayed directly into the surface of the molten […]

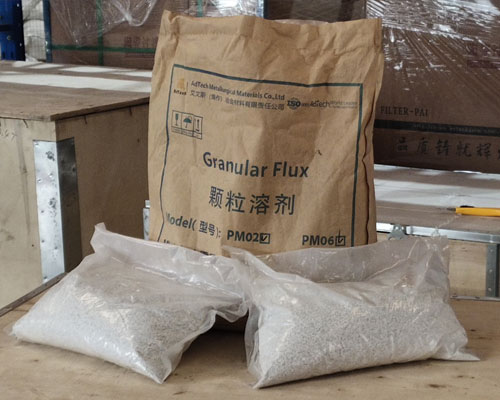

Granular refining fluxes have been used in research at home and abroad with good results. Due to the boiling effect of the N2 and CO2 generated by the reaction, the hydrogen and non-metallic inclusions will be taken out of the aluminum liquid when the bubbles float up, so the degassing effect of this mixture is […]

Fluxes for aluminum melt can also be used to minimize oxide formation. For this reason, melts containing magnesium are often protected by the use of salts that form liquid layers, most often of magnesium chloride, on the melt surface. These fluxes, termed covering fluxes, must be periodically removed and replaced. The common practice of flux […]

Aluminum alloy granular flux is a new, efficient, and environmentally friendly additive. It is used in the secondary refining process of aluminum alloy smelting and aluminum alloy casting. Its main function is to remove slag (miscellaneous) in the aluminum melt and reduce the hydrogen content, reduces aluminum loss. Different from the traditional powdery flux, the […]