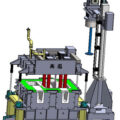

Molten aluminum degassing machine is a kind of on-line degassing equipment. Its design and production are carried out independently. It is used for the degassing and purification of molten aluminum. The degassing box is cast and sintered with high strength imported castable, which has good thermal shock resistance. The insulation layer outside the box is […]

SEO

Degassing refining equipment is an important equipment to remove hydrogen content, inclusions and alkali metals in molten aluminum. The solubility of hydrogen in molten aluminum is very high, which will reduce the physical properties and machinability of castings. In order to cast high quality castings, the hydrogen content in molten aluminum must be controlled at […]

The aluminum degassing unit with three rotors is specially designed to provide on-line degassing for flutes with large molten aluminum flow, high gas content and many impurities. Through three stirring rotors which can independently control the speed and gas flow rate, it can provide strong degassing refining capacity for more molten aluminum. The degassing equipment […]

Molten aluminum degasser is a degassing and purification product. It uses the most advanced control technology, man-machine interface, and is controlled by PLC computer program. According to the alloy flow rate and purification degree, the purity of aluminum melt is ensured. In terms of technology, the single rotor degassing box adopts a new concept and […]

Molten aluminum degassing system is an advanced molten aluminum purification equipment with built-in advanced heating elements. According to the casting process requirements, the internal temperature is effectively controlled, and the on-line degassing device is used to remove gas and harmful impurities in aluminum and aluminum alloy melt. Aluminum and aluminum alloy melts are introduced into […]

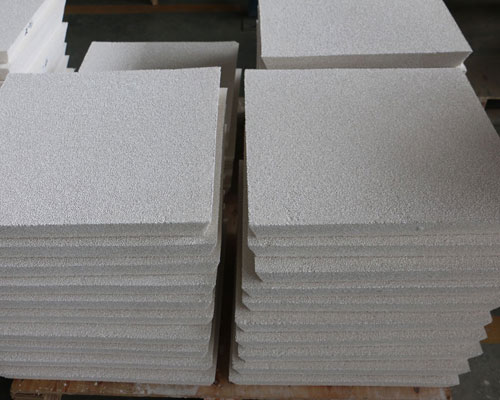

Asian foundry filter agent has been authorized by China’s manufacturers to sell foam ceramic filters to local aluminum plants. The purification purpose of ceramic foam filter in aluminum foundry is to remove alumina slag and hydrogen from aluminum melt to improve the process and mechanical properties of aluminum materials or products. In the process of […]

The Asian casting filter is the most commonly used ceramic foam filter in the aluminum casting industry. Most plants use degassing process in the treatment of molten aluminum, and use 30ppi and 40ppi CFF to filter aluminum slag. Ceramic foam filter plates of 10-40 PPI are usually used for common aluminum castings. Ceramic filter plates […]

Ceramic casting filter is an economical and convenient method to remove aluminum inclusions, which has been widely used to filter molten aluminum. The size of ceramic foam filter plates varies from 7 inches to 26 inches, and the sizes of through-hole vary from 20ppi to 60ppi. There is an 8mm aluminum silicate gasket around the […]

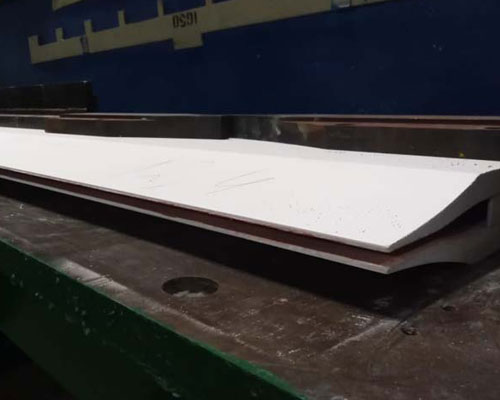

Feed caster nozzle often explodes due to the accumulation of gas in the nozzle cavity during casting and rolling. By drilling holes on the surface of the caster nozzles and using far-infrared nozzle baking technology, the possibility of gas accumulation in the nozzle chamber of hard materials can be greatly reduced. The feed caster nozzle […]

The quality of the continuous casting aluminum strip is directly affected by the quality of Feeder Nozzle Cavity. The special process of casting nozzle material can effectively prevent molten aluminum from corroding casting nozzle and avoid carbonization. Fracture tissue is a fine and uniform layered fiber structure, which can prevent the existence of flocculent tissue. […]