Aluminum silicate high-temperature tap out cone: ceramic fiber special-shaped parts are made of high-quality ceramic fiber cotton as raw material and made by vacuum forming process. The purpose of developing this product is to make rigid and self-supporting special-shaped products with superior high-temperature performance. Ceramic fiber special-shaped parts are special-shaped products that meet the needs […]

1 On-line degassing unit system operating procedures for degassing aluminum Daily inspection content of online degassing unit: Check whether the heater works normally every day: How to identify whether the heater is normal: If the temperature value displayed by the temperature control meter is lower than the set value and the corresponding ammeter has no […]

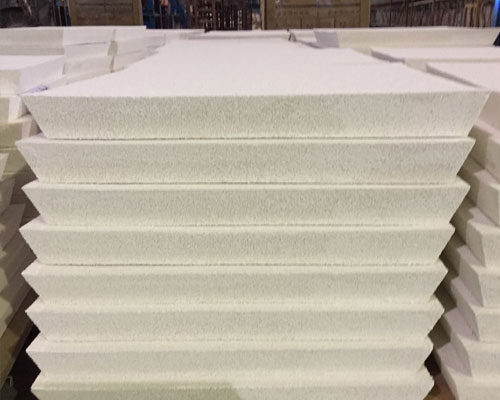

The filter box is an essential configuration for forming a stable filter cavity when using porous ceramic filters to filter aluminum and aluminum alloy melts. It has excellent heat resistance, good heat preservation performance, high strength, strong resistance to mechanical shock, and standard molding dimensions. Effectively realize the filtration efficiency of the ceramic filter plate […]

1. The online rotary degassing equipment adopts a sealed design, which prevents the secondary pollution caused by the entry of outside air; 2. Two-body structure design, the degassing part of the degassing unit, and the electric heating part can be rotated (the rotation range is designed according to the site situation), and it has a […]

The liquid aluminum plug is also called the liquid aluminum plug cap and liquid aluminum plug. It is made of high-quality tap out cone cotton and is made by a vacuum-forming process. The purpose of developing this product is to make it rigid with excellent high-temperature performance and self-supporting strength. The special-shaped products and aluminum liquid […]

Pollution problem after refining gas, hydrogen degassing discharge Due to the increasing requirements for the purification of aluminum melts in many production plants, In particular, to effectively remove alkali metals from aluminum melts, use inert Mixed refining of hydrogen degassing and chlorine in the production process will have a certain amount of exhaust hydrogen degassing […]

The aluminum casting fluxes are solid substances (usually a mixture of chloride and fluoride) used in aluminum smelter and foundries. The purpose is to reduce the oxidation of the melt, reduce the penetration of hydrogen in the atmosphere, absorb the non-metallic inclusions suspended in the melt, keep the furnace/ladle clear of the walls of the […]

The ceramic filter for casting can effectively remove the large impurities in the molten aluminum and absorb the micron-level fine particles of impurities, thereby improving the surface quality, improving the product performance, improving the microstructure and increasing the output. It is widely used in the production of aluminum profile, aluminum foil and aluminum alloy. Ceramic […]

Foam ceramic filter for aluminum casting filtration is very important for the quality control of aluminum. It can remove primary and secondary liquid/solid non-metallic inclusions in the metal melt, simplify the casting system, prevent inclusion defects, improve the mechanical properties of the casting, reduce the machining allowance of the casting, improve the surface finish of […]

The longer the launder and trough, the greater the possibility and degree of secondary pollution. In theory, after refining in the furnace, online degassing and slag removal, the purity of the aluminum alloy melt should reach a very high level. But actual results are usually not ideal. One of the important reasons is the secondary […]