From the current situation of aluminum melt purification treatment technology, a lot of work has been done, and some advanced Degassing And Purification System has been developed, which promotes the development of melt purification technology. However, most of these methods are designed from the point of view of dehydrogenation and purification (that is to say, […]

The slag removal ability of the Aluminum Drossing Flux is determined by the adsorption and dissolution of the oxidized inclusions in the melt by the flux and the chemical interaction between the flux and the melt. Because the oxide inclusions are not wetted by the molten aluminum, the interfacial tension between the two is very […]

The refining agent is generally introduced into the aluminum alloy melt with inert gas as a carrier for degassing and impurity removal. Refining agent is also called Aluminum Flux, Aluminum Casting Flux, Flux Aluminium, Aluminium Degassing Tablets, Flux For Aluminum Melting, Flux For Melting Aluminum Cans, Aluminium Casting Flux, Aluminum Casting Foundry Flux, Aluminum Degassing […]

At present, aluminum is the most used non-ferrous metal in the world, and aluminum products are widely used in various fields of the national economy. Compared with the production of electrolytic aluminum, the use of recycled aluminum can save 95% of energy such as water and electricity. The waste gas and waste generated in the […]

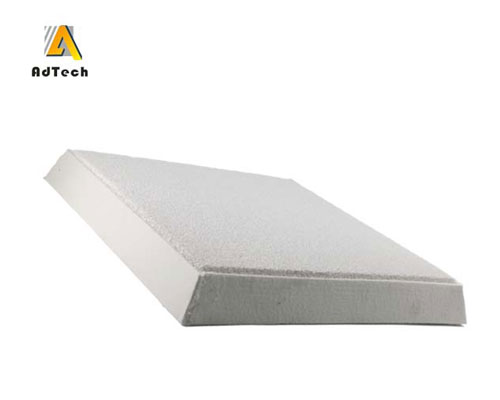

Ceramic Foam Filters Manufacturing Process uses polyurethane foam as the carrier. After hydrolysis, the foam is immersed in the coating made of ceramic powder, binder, sintering aid, suspending agent, etc., and then the excess coating is squeezed out, so that the ceramic coating is evenly coated on the framework of the carrier to form a […]

The alumina filter can reduce or eliminate casting defects through mechanical interception, rectifying scum and deep adsorption through three filtering and purification mechanisms, and improve alloy yield and processing performance. In the process of melting and pouring of aluminum and its alloys, defects such as inorganic inclusions and shrinkage holes are the main reasons that […]

Since the organic foam impregnation method successfully developed CFF filters for aluminum melt filtration in 1978, it has been rapidly promoted in the aluminum industry because of its low cost, high filtration efficiency and adaptability. Developed countries have developed early research and development of CFF filters for aluminum, with many innovations and many evaluation methods. […]

In the modern aluminum melt purification process, Casting Filters filtration is the last purification process close to the casting terminal. Before that, 6 ~ 80% of inclusions and gases have been removed through flux refining in furnace, medium and non-media adsorption, but finer inclusions (generally < 15m in particle size) are distributed in the melt […]

The area of metal passing through the Filter Foundry should be large enough to prevent the casting speed and pouring time affected by the installation of the filter. Therefore, the factors of slag collection, filter and damping should be considered in the process. Therefore, the ratio of the cross-section area of the filter to the […]

AdTech Ceramic Filter Price is reasonable, and the filling ability of aluminum alloy liquid is improved by ceramic foam filter filtration. Ceramic Foam Filter Filtration Removing impurity and slag: purifying aluminum alloy liquid and removing hydrogen: after filtration, the viscosity of aluminum alloy liquid is reduced, and the fluidity of aluminum alloy liquid is increased […]