Foam Ceramic Filter Sumatra Aluminium is widely used in aluminum profile, aluminum foil, aluminum alloy production fields. In the process of aluminum ingots melting and casting, the large inclusion in the liquid aluminum, the absorption of micron grade small inclusion particles, can improve the surface quality, improve product performance, improve the microstructure, improve the rate […]

Foundry Feeding Tip Cavity is used for the aluminum strip casting process. Molten aluminum is fed from the elongated casting tip into the nip between two counter-rotating water-cooled rolls. The molten aluminum is cooled when it comes into contact with the rolls and cools as it passes between the rolls, thereby forming a wide cast […]

Foundry Feed Casting Nozzle is used for all kinds of two-roll continuous Casting and rolling machines. The distribution state of the flow field and temperature field directly affects the plate shape. The surface of the aluminum silicate Nozzle is treated with special coating of aluminum titanate, and the special process can effectively prevent the aluminum […]

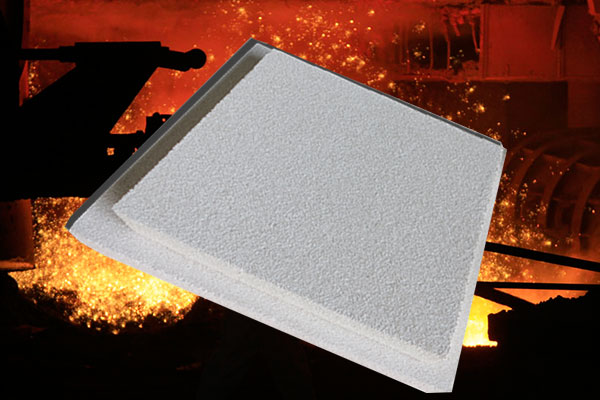

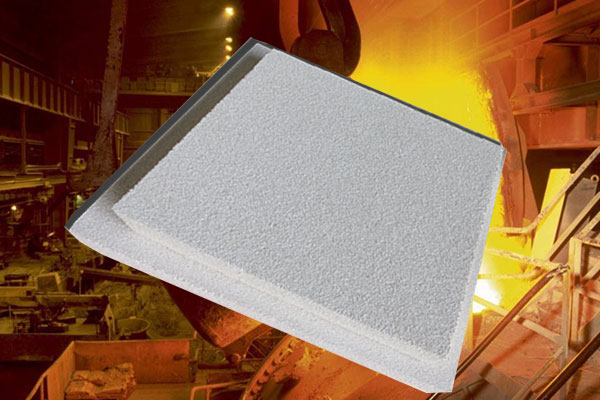

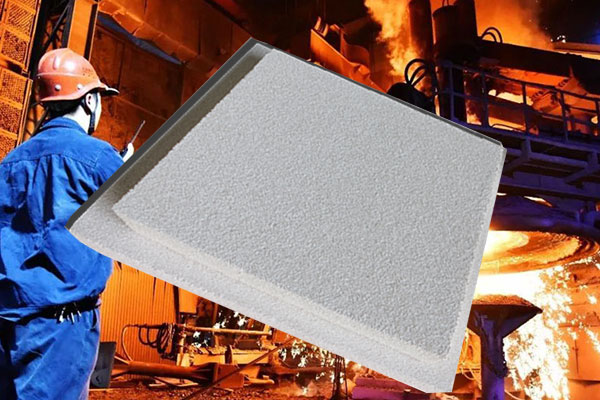

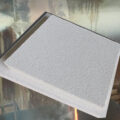

Ceramic Foam Filter Arvida Aluminium is the most effective method to remove inclusions from Molten Aluminum. Foam ceramic filter has multi-layer network, multi-dimensional through holes, holes connected to each other. During molten metal filtration, liquid aluminum carries inclusions along tortuous channels and pores, which are directly captured, adsorbed and deposited when contacting the foam framework […]

Ceramic Foam Filter Prime Aluminum can effectively remove large inclusions in liquid Aluminum and adsorb small inclusion particles with micron size, so as to improve surface quality and product performance. It can increase the compressive sealing of aluminum ingot aluminum rod, enhance elongation and tensile strength, improve the surface finish of casting, improve the fluidity […]

Ceramic Foam Filter Pakistan Aluminum uses a set of strict manufacturing technology from material selection, pulp mixing, carrier pretreatment, infrared drying, sputtering coating and microwave drying, and then to the temperature field control of roasting. In the casting process of aluminum bar and aluminum ingot, the mechanism of foam ceramic plate filtration and purification of […]

Ceramic Foam Filter Korba Aluminium is an important link in the process of aluminum alloy smelting, and is one of the alloying purification and refining treatment technologies in the process of aluminum alloy smelting. It has long been an important means to remove non-metallic inclusions from aluminum alloy melt by means of in-furnace particle refiner […]

Ceramic Foam Filter Aluminum Pakistan is mainly used in the purification process of Aluminum and Aluminum alloy production, which can effectively remove all kinds of inclusion in Aluminum water with fineness up to micron level. Ceramic Foam Filter Aluminum Pakistan can change the water into a stable laminar flow, which is conducive to punching. It […]

Tap Out Cone for Aluminium Smelter is made by mixing high-purity aluminum silicate fiber with inorganic binder and vacuum forming. Ceramic Fiber Tap Out Cone is widely used in aluminum alloy melting furnaces to control the production flow of molten aluminum. Tap Out Cone for Aluminium Smelter features: 1. Aluminum tapping cone is used for […]

Aluminum alloy refining degassing specifically refers to the removal of inclusions and gases in the aluminum alloy. Because this process is often carried out simultaneously, it is customary to collectively refer to this process as refining in production. The high degassing efficiency can greatly reduce the waste caused by bubbles and inclusions and greatly increase […]