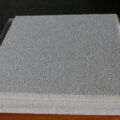

Ceramic Foam Filter for Albras can effectively filter out impurities, including impurities that are much smaller than the filter pores. The large inclusions on the filter surface are physically shielded and retained, and the small inclusions are attracted to the filter surface, sidewalls or pores. This ceramic filter can also reduce turbulence and comb the entire chaotic flow of molten metal.

The filtration efficiency of ceramic foam filters in Albras aluminum plant is closely related to their correct installation and use. It is also necessary to prevent the filtered aluminum liquid from being contaminated again.

Albras is an aluminum smelter, which started construction in 1981 and was constructed in two phases with a total investment of 1.4 billion US dollars. The first phase of the project was completed in 1986 and 1991 respectively. Currently, ALBRAS has 4 electrolyzer production lines, 960 electrolyzers, and an annual production capacity of 450,000 tons. In July 2015, ALBRAS commemorated the 30th anniversary of the start of operations. The primary aluminum ingots produced by ALBRAS are exported to Japan and other countries, as well as to the Brazilian domestic market. NAAC has the right to receive 220,000 tons of primary aluminum ingots produced by ALBRAS each year, equivalent to about 10% of Japan’s total imports of primary aluminum ingots.

Albras is 51% owned by Hydro and 49% is owned by Nippon Amazon Aluminium. The total capacity of the smelter is 460,000 tons per year-producing high-purity aluminum and casting alloys. The smelter is Brazil’s largest producer of primary aluminum and has been supplying high-purity aluminum ingots for domestic and foreign markets since 1985.

The selection of the size of the Ceramic Foam Filter for Albras molten metal filtration must consider the flow range of the specific casting, the highest level of the metal during filtration, the total filtration volume, and the cleanliness of the primary aluminum liquid.

Filtration treatment before melting cannot be ignored: ordinary slag cleaning furnaces such as aluminum melting furnaces and holding furnaces; refining in the melting furnace. In particular, the online degassing device is still necessary because it can not only reduce the hydrogen content of the melt, but also remove some non-metallic inclusions.

The molten metal filter is suitable for the square refractory filter box: both are sealed to prevent the metal from flowing into the pouring box from the gap without being filtered, and also to prevent the filter plate from floating in the aluminum water.

Preheat before use: Preheat to remove moisture and promote initial transient filtration. Electric heating or gas heating can be used for preheating. Under normal circumstances, it takes about 15 minutes.

No slag is left during normal filtration, avoid knocking and vibrating the filter plate. At the same time, the launder should be filled with molten aluminum to avoid excessive interference of molten aluminum.