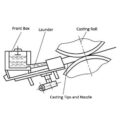

Install the molten aluminum castertip on the steel structure fixture, fix it with screws, then install the feed pipe and the front box, and check whether the joints are tightly connected to prevent leakage when the vertical plate is discharged. Put the assembled pouring system into the drying box, dry, and preheat. The furnace temperature […]

According to the actual production situation of cast rolling, the dissolved hydrogen is the most easily dissolved gas in molten aluminum, and its content accounts for 90% of the dissolved gas. Hydrogen is an important cause of porosity, loose strip and peeling in casting and rolling and the next process (aluminum alloy is easy to […]

Continuous casting and rolling production of slabs is the key to producing high-quality aluminum slabs. The quality of the vertical slabs directly affects the internal structure and surface quality of the aluminum slabs. In the process of erecting the slab, often after the slag ran away or the slab was discharged for a period of […]

Foam ceramic filter is the last technology for molten aluminum filtration. It is particularly important to choose the foam ceramic filter board. According to the environment of each foundry, choose the best ceramic foam filter and obtain high cleanliness of molten aluminum. The choice of foam ceramic filter plate depends on the impurity content in […]

The technology of removing non-metallic inclusions in the molten aluminum alloy, adopting the furnace flux treatment, and the technology of molten alu foam ceramic filter filtration outside the furnace has long become an important method for the purification of molten aluminum. Reflected in the alloying, purification, and refinement processing technology of the smelting process. The […]

The molten aluminum ceramic filter plate can effectively remove the large inclusions in the molten aluminum, and absorb the fine inclusion particles of micrometer size, improve the surface quality, improve the product performance, improve the effect of the microstructure, and increase the yield. It is widely used in the production of aluminum profile, aluminum foil, […]

Molten aluminum purification equipment is usually installed between the furnace outlet and the filter box. The melt flows into the box of degassing device, and the inert gas is broken by rotating the rotor, thus forming a large number of dispersed bubbles in the aluminum melt. After collision, capture, surface adsorption and partial pressure, hydrogen […]

The aluminum melt casting launder consists of a solid low carbon steel shell lined with refractory. In addition to low thermal conductivity and high thermal fatigue strength, it also has the largest non wettability. Before and after firing, we manually check all prefabricated fire resistant launders to ensure the highest quality. If you need, our […]

Molten aluminum runner system is an important part of any foundry. The well-designed launder system can promote the smooth and efficient operation of casting workshop, and the rapid transfer between casting workshops is very important. Clean, low turbulence runner plays an important role in the production of high quality products. The size and grade of […]

Molten aluminum insulated runner is used between on-line degassing filter equipment and continuous casting mill. It has a reusable or reusable lining. Using new high silicon melting material molding technology, it has the properties of corrosion resistance, no aluminum sticking and no pollution of aluminum liquid. It can meet the production process of micron aluminum […]